Why Automotive Plastic Injection Molding is Essential for Modern Manufacturing

In today's rapidly evolving automotive industry, the demand for efficient and innovative manufacturing processes is at an all-time high. Among the various techniques employed, automotive plastic injection molding stands out as a pivotal technology that facilitates the production of complex and durable parts with precision. This method not only enhances the design flexibility of automotive components but also significantly reduces production costs and time. As vehicle manufacturers strive to meet stringent safety regulations and sustainability goals, automotive plastic injection molding has emerged as an essential technique that aligns with these industry needs.

The benefits of automotive plastic injection molding extend beyond mere efficiency; it allows for the creation of lightweight and robust parts that contribute to improved fuel efficiency and overall vehicle performance. The ability to use a diverse range of plastic materials further supports innovation in design, enabling manufacturers to meet consumer preferences for both aesthetics and functionality. As we delve deeper into the significance of automotive plastic injection molding, it becomes evident that this process is not only a cornerstone of modern manufacturing but also a key enabler of future advancements in the automotive sector.

The Evolution of Automotive Plastic Injection Molding Techniques

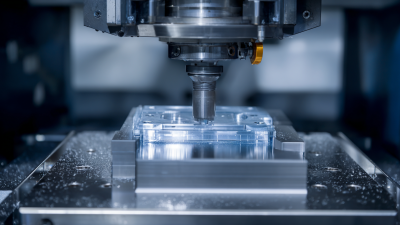

The evolution of automotive plastic injection molding techniques has significantly transformed the manufacturing landscape of the automotive industry. Initially, early methods were limited in precision and variety, often relying on basic mechanical processes that did not fully harness the potential of plastic materials. As technology advanced, so did the capabilities of injection molding, leading to the development of more sophisticated machinery and techniques that allowed for intricate designs, reduced cycle times, and enhanced material properties.

With the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM), the accuracy and efficiency of plastic injection molding improved dramatically. Engineers can now simulate and optimize molds before production, minimizing errors and waste. Innovations such as multi-material injection molding enable the creation of complex components that blend different types of plastics, enhancing the functionality and aesthetic appeal of automotive parts. These advancements have not only streamlined production processes but also contributed to lighter, more fuel-efficient vehicles by allowing manufacturers to replace heavier metal parts with high-performance plastic components. As the automotive industry continues to embrace sustainability, the role of advanced plastic injection molding techniques will only grow more vital in meeting environmental standards while maintaining high-quality production.

Market Trends: Growth of Automotive Plastic Molding (Forecasts and Data)

The automotive plastic molding market has seen significant growth in recent years, driven by the increased demand for lightweight and fuel-efficient vehicles. According to a report by MarketsandMarkets, the global automotive plastic market is projected to reach USD 49.78 billion by 2026, growing at a CAGR of 11.6% from 2021 to 2026. This surge in demand for plastic components is largely attributed to the automotive industry's shift towards more sustainable production processes and innovation in material technology.

Moreover, the shift towards electric vehicles (EVs) and hybrid models has further propelled the need for advanced plastic solutions. A recent analysis by Grand View Research indicated that the adoption of plastics in vehicle production can result in a weight reduction of up to 50%, contributing to lower energy consumption and improved overall vehicle efficiency. As manufacturers increasingly seek sustainable design, the incorporation of recyclable and lightweight plastics is becoming imperative, underscoring the importance of automotive plastic injection molding in modern manufacturing.

The growth trajectory of automotive plastic molding also reflects changes in consumer preferences. With rising environmental awareness, consumers are favoring vehicles that not only provide better performance but also adhere to eco-friendly practices. In this context, the use of advanced plastics not only fulfills performance needs but also aligns with the sustainability goals that are increasingly prioritized in manufacturing processes. These trends are reshaping the landscape of automotive manufacturing, making plastic injection molding an essential component for future innovations in the industry.

Advantages of Plastic Injection Molding in Automotive Components

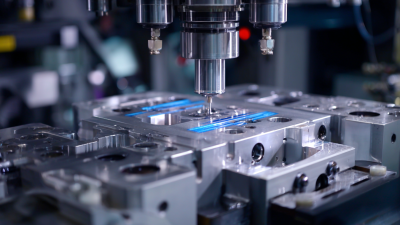

The automotive industry is increasingly relying on plastic injection molding as a vital manufacturing process, particularly due to its significant advantages in producing automotive components. One notable statistic from the Plastics Industry Association indicates that the automotive sector accounted for approximately 35% of all plastic consumption in 2022, reflecting the material's essential role in vehicle construction. Plastic injection molding facilitates the high-volume production of intricate parts, allowing manufacturers to achieve complex geometries that would be difficult or costly to produce with traditional metalworking methods.

Moreover, the benefits extend to weight reduction and cost efficiency, which are crucial in today’s automotive design. According to a report by the Society of Automotive Engineers, switching to plastic components can reduce vehicle weight by up to 20%, translating to improved fuel efficiency and lower emissions. Furthermore, the fast cycle times associated with injection molding can lead to significant reductions in production costs. The production of a single plastic component can take as little as 15 to 30 seconds, compared to several minutes for metal alternatives, enabling manufacturers to meet growing consumer demands swiftly while maintaining quality.

The integration of plastic injection molding is shaping the future of automotive manufacturing by enhancing innovation and sustainability in vehicle design.

Environmental Impact and Sustainability in Automotive Plastics

The automotive industry has witnessed a notable transformation with the increasing use of plastic injection molding processes. This technology not only enhances production efficiency but also contributes significantly to environmental sustainability. Injection molding allows manufacturers to create complex components with precision, reducing material waste and energy consumption during the manufacturing process. By utilizing advanced materials that are lightweight yet strong, vehicle manufacturers can improve fuel efficiency while decreasing emissions, aligning with global trends towards sustainability.

Moreover, the environmental impact of automotive plastics extends beyond production. The lifecycle of these materials must be considered, from sourcing to end-of-life disposal. Innovations in recycling technologies for automotive plastics are crucial; they enable old components to be repurposed, minimizing landfill waste and promoting a circular economy. As companies embrace biodegradable and recyclable plastic alternatives, they are taking significant strides towards reducing their carbon footprint. The integration of sustainability into the automotive supply chain will not only meet regulatory requirements but also resonate with environmentally-conscious consumers, paving the way for a greener automotive future.

Future Innovations Shaping Automotive Plastic Injection Molding

The automotive industry is experiencing a significant transformation, particularly through advancements in plastic injection molding technologies. One of the most promising future innovations is the incorporation of smart materials and advanced polymers, which can enhance the performance and sustainability of automotive components.

According to a recent industry report by MarketsandMarkets, the market for automotive plastics is projected to grow from $23.7 billion in 2022 to $36.6 billion by 2027, driven by the increasing demands for lightweight materials and fuel-efficient vehicles. These materials are not only reducing the weight of vehicles but also enabling greater design flexibility, which is crucial for meeting the aesthetic and functional requirements of modern cars.

Moreover, integrating automation and artificial intelligence into the injection molding process is expected to streamline production and improve efficiency. The Plastics Industry Association notes that automation can lead to a 20-30% decrease in production costs and a significant reduction in waste, which aligns with the automotive industry's push for sustainable manufacturing practices. Future innovations in 3D printing alongside injection molding are also making it possible to produce complex geometries that were previously unattainable, further enhancing the creative capacity for automotive designers.

This synergistic approach not only drives the evolution of automotive parts but also ensures that the industry keeps pace with stringent environmental regulations and market demands for greener solutions.

Related Posts

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

Exploring Innovative Alternatives to Mold Plastic Injection in Modern Manufacturing: Trends and Insights

-

How to Optimize Your Plastic Injection Tooling Process for Maximum Efficiency

-

How to Optimize Your Production Process with Medical Injection Moulding Techniques

-

Understanding the Essential Role of Injection Molding Tooling in Modern Manufacturing

-

Revolutionizing Healthcare: The Impact of Medical Injection Molding on Patient Outcomes in 2023