Top Benefits of Short Run Injection Molding in Custom Manufacturing

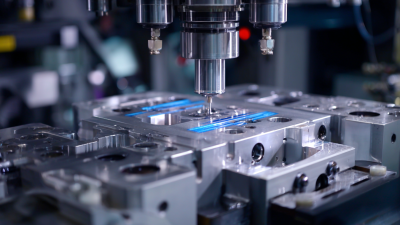

In the realm of custom manufacturing, short run injection molding has emerged as a pivotal process for businesses seeking efficiency and flexibility in production. This method allows manufacturers to produce limited quantities of parts and components with precision and speed, making it an ideal choice for prototyping, market testing, and fulfilling niche demands. The ability to produce small batches at a reduced cost without compromising on quality presents significant advantages over traditional mass production techniques.

Short run injection molding not only accelerates the time-to-market but also enables manufacturers to refine their designs based on consumer feedback and evolving market trends. This adaptability plays a crucial role in fostering innovation and supporting companies in their quest to stay competitive. Moreover, the reduced waste and lower investment in mold production further enhance the appeal of this process, making it a smart choice for startups and established firms alike. By harnessing the benefits of short run injection molding, manufacturers can effectively meet their specific needs while optimizing resources, setting the stage for sustainable growth in custom manufacturing.

Benefits of Short Run Injection Molding for Custom Manufacturing

Short run injection molding is an increasingly popular solution in custom manufacturing, offering several key advantages tailored to meet specific production needs. One of the primary benefits is cost efficiency for low-volume production. Traditional manufacturing methods often come with high setup costs and minimum order requirements, making them impractical for smaller batches. Short run injection molding allows manufacturers to produce smaller quantities without incurring the excessive costs typically associated with larger runs, thus enabling businesses to manage their budgets more effectively.

Another significant advantage is the speed and flexibility of production. In industries where product life cycles are short, businesses need to adapt quickly to market demands. Short run injection molding facilitates rapid prototyping and iterative design changes, allowing manufacturers to tweak designs based on immediate feedback. This responsiveness not only helps in refining the product but also speeds up the time to market, ensuring that businesses stay competitive. Additionally, the ability to produce custom molds specifically designed for short runs means that companies can cater to unique specifications without the limitations often imposed by traditional manufacturing techniques.

Cost-Effectiveness of Short Run Injection Molding Techniques

Short run injection molding techniques offer significant cost-effectiveness in custom manufacturing, especially for businesses looking to produce limited quantities of parts without sacrificing quality. By reducing the upfront investment in tooling and materials, companies can streamline their production processes and minimize waste. This method is particularly beneficial for startups and small businesses that require flexibility and efficiency in their operations.

Tips for optimizing costs with short run injection molding include focusing on design efficiency. Simplifying part designs can reduce production time and material costs. Additionally, collaborating closely with manufacturers during the design phase can help identify potential issues early, leading to cost savings down the line.

Another effective strategy is to leverage advanced technologies, such as 3D printing for initial prototypes, before transitioning to injection molding for final production. This allows for faster iterations and adjustments, ultimately leading to better investments in the manufacturing process. By being strategic in the approach to short run injection molding, businesses can achieve high quality at competitive prices, aligning with their operational goals without overspending.

Faster Turnaround Times in Custom Manufacturing Processes

Short run injection molding is revolutionizing the custom manufacturing landscape by significantly enhancing turnaround times. In traditional manufacturing processes, especially for large production runs, lead times can stretch into weeks or even months. However, recent industry reports indicate that short run injection molding can reduce production times to mere days, enabling manufacturers to meet urgent market demands swiftly. According to a study by the Society of Manufacturing Engineers, 68% of manufacturers reported that faster turnaround times directly improve their competitive edge by allowing quicker response to customer needs.

Moreover, the flexibility offered by short run injection molding allows for rapid prototyping and iterative design improvements. This approach fosters innovation, as manufacturers can produce small batches to test market responses or refine product quality without the burden of hefty investment in large-scale production. A report from the American Society of Mechanical Engineers suggests that companies utilizing short run injection molding techniques can bring products to market up to 40% faster than those relying solely on traditional methods. This accelerated pace not only benefits manufacturers but also meets the consumer's increasing demand for quicker availability of customized products, making it an essential strategy in today’s fast-evolving market.

Top Benefits of Short Run Injection Molding in Custom Manufacturing

| Benefit | Description | Impact on Turnaround Time |

|---|---|---|

| Lower Initial Costs | Short run injection molding reduces tooling costs, making it more feasible for small batches. | Enables faster project initiation due to lower upfront investment. |

| Rapid Prototyping | Allows for quick iteration and design changes, facilitating faster product development cycles. | Speeds up testing and approval processes. |

| Flexibility in Production | Short runs can accommodate changes in design or quantity without significant delays. | Reduces time lost in retooling for new designs. |

| Reduced Waste | Minimizes material overstocking, aligning production closely with demand. | Shortens lead time by aligning production with immediate requirements. |

| Easier Market Testing | Facilitates the introduction of new products in smaller amounts to evaluate market response. | Speeds up time to market for new products. |

Increased Flexibility for Design Modifications and Prototyping

Short run injection molding offers unparalleled flexibility in

design modifications and prototyping, making it an ideal choice for custom manufacturing. This approach allows engineers and designers to create multiple iterations of a product quickly and economically. As they receive feedback from stakeholders or test the product in real-world scenarios, they can easily adjust the design based on practical insights.

The reduced lead time associated with short run production means that manufacturers can respond agilely to changes, ensuring that the final product meets the desired specifications and customer expectations.

Additionally, this method supports rapid prototyping, enabling teams to transition from concept to production in a matter of weeks rather than months. Designers can experiment with different materials and configurations without committing to large-scale production runs. This not only accelerates the development process but also minimizes waste and costs associated with traditional manufacturing methods.

By embracing the flexibility of short run injection molding, companies can innovate more efficiently, continuously refining their products while keeping pace with dynamic market demands.

Optimized Material Utilization in Short Production Runs

Short run injection molding stands out as a valuable solution in custom manufacturing, particularly when it comes to optimizing material utilization. This process is designed for smaller production quantities, allowing manufacturers to minimize waste effectively. By using targeted quantities of raw materials, companies can ensure that every unit produced is necessary, reducing excess inventory and lowering overall costs. Short run injection molding allows for greater flexibility in design, enabling manufacturers to experiment with various materials and configurations without committing to large batches.

Tips for maximizing material utilization during short production runs include careful planning and simulation of the molding process. Utilizing advanced software can help identify the most efficient gating and runner systems, cutting down on scrap material. Additionally, consider using recyclable or biodegradable materials to further enhance sustainability without sacrificing quality. Manufacturers should also focus on regular maintenance of their injection molding machines to ensure optimal performance, which can significantly improve material efficiency.

Moreover, collaborating closely with design engineers is crucial. Early involvement in the design phase enables better identification of potential issues that could lead to material waste. Simple design adjustments, such as reducing wall thickness or optimizing part geometry, can lead to substantial savings. By leveraging these strategies, companies can not only enhance their material efficiency but also achieve greater overall profitability in short run injection molding projects.

Related Posts

-

Understanding the Essential Role of Injection Molding Tooling in Modern Manufacturing

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry

-

Quality Driven Global Success of Prototype Injection Molding from China

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

Exploring Innovative Alternatives to Injection Moldable Plastics for Sustainable Production

-

7 Reasons Why Short Run Injection Molding is the Best Choice for Your Business