Common Challenges Faced in Mold Plastic Injection Processes

The mold plastic injection process is a pivotal technique in the manufacturing landscape, responsible for producing a staggering 30% of all plastic products globally, as reported by the Plastics Industry Association. However, this sophisticated method is not without its challenges. From issues like warpage and sink marks to the complexities of achieving optimal temperature control, manufacturers face various roadblocks that can compromise product quality and production efficiency. According to a study by Joule, nearly 50% of molded products fail at some point due to inadequate processing conditions. Therefore, understanding these common challenges in mold plastic injection is crucial for industry professionals aiming to refine their operations and enhance product reliability. In this blog, we will delve into the prevalent difficulties faced during the mold plastic injection process and discuss effective strategies to mitigate them.

Common Defects in Mold Plastic Injection: 5 Key Challenges Manufacturers Encounter

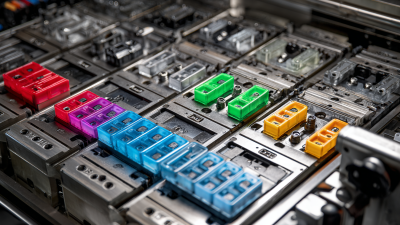

Mold plastic injection processes are essential in manufacturing, but they come with their own set of challenges. One prominent issue is the presence of defects such as register rings and sprue blemishes, which can significantly affect the quality of the final product. Manufacturers need to be vigilant in identifying these defects early in the design phase to avoid costly rework and material waste.

Mold plastic injection processes are essential in manufacturing, but they come with their own set of challenges. One prominent issue is the presence of defects such as register rings and sprue blemishes, which can significantly affect the quality of the final product. Manufacturers need to be vigilant in identifying these defects early in the design phase to avoid costly rework and material waste.

Tips for minimizing defects include: implementing a simulation-driven design optimization process that focuses on reducing cycle time and optimizing injection parameters. Regular assessment of mold designs is critical; leveraging techniques like Six Sigma and machine learning can help in analyzing defect trends and improving overall quality. Additionally, integrating a feature-based assembly library can streamline the design process and ensure that potential deficiencies are addressed proactively, resulting in a more efficient mold design and manufacturing process.

Attention to detail in the mold design stage and the adoption of advanced analytical methods can lead to significant improvements in part quality and operational efficiency. By tackling these common challenges head-on, manufacturers can enhance their productivity and deliver better products to the market.

Understanding Cycle Time: 7 Factors Impacting Efficiency in Injection Molding Processes

Injection molding is a complex manufacturing process that faces several challenges, particularly when it comes to optimizing cycle time. Cycle time directly influences productivity and cost efficiency, making it crucial for manufacturers to understand the factors affecting it. One significant factor is the material used; different polymers have unique cooling times, which can drastically alter the overall cycle. For instance, high-temperature materials may require longer cooling periods, extending cycle time.

Another important aspect is mold design. A well-designed mold ensures even temperature distribution and efficient cooling, reducing cycle time. Additionally, the injection speed plays a pivotal role; injecting too quickly can lead to defects, while a slower approach may increase cycle time unnecessarily. Lastly, the machine's technical capabilities, including clamping force and control systems, must be considered. Regular maintenance and updates can enhance machine performance, ultimately streamlining the injection molding process and minimizing cycle times.

The Cost of Poor Quality: 6 Financial Implications of Injection Molding Failures

In the world of injection molding, quality control is paramount. The ramifications of poor-quality molds can be severe, leading to significant financial losses. According to a report from the Society of Plastics Engineers, costs associated with injection molding failures can reach up to $3 million annually for companies that manufacture complex parts. This includes costs related to scrap materials, rework, and downtime, which can severely impact overall productivity and profitability.

To mitigate these costs, manufacturers should focus on optimizing their processes. Implementing quality assurance protocols at every stage of production can greatly reduce the likelihood of defects. For instance, regular maintenance of machinery can prevent unplanned breakdowns and ensure consistent output quality. Furthermore, investing in advanced technologies like real-time monitoring systems can help identify potential issues before they escalate, ultimately saving time and money.

Tip: Consider conducting a root cause analysis on past failures to identify common patterns, which can inform your quality control strategies and reduce future defects. Another effective strategy is to foster strong communication among team members, ensuring that everyone is aligned on quality expectations. This collaborative approach not only promotes accountability but also encourages innovative solutions to common challenges.

Common Challenges Faced in Mold Plastic Injection Processes - The Cost of Poor Quality: 6 Financial Implications of Injection Molding Failures

| Challenge | Financial Impact ($) | Frequency (%) | Solution |

|---|---|---|---|

| Poor Part Quality | $50,000 | 30% | Regular Quality Inspections |

| Increased Scrap Rate | $25,000 | 20% | Implementing Lean Manufacturing |

| Downtime due to Machine Failure | $40,000 | 15% | Preventative Maintenance |

| Delayed Production Times | $30,000 | 25% | Streamlining Processes |

| Excessive Labor Costs | $15,000 | 10% | Training & Automation |

| Regulatory Non-compliance | $70,000 | 5% | Regular Compliance Audits |

Optimizing Material Selection: 4 Key Reasons for Issues in Plastic Injection Molding

Optimizing material selection is crucial in overcoming common challenges faced during the plastic injection molding process. One significant reason for issues in this domain lies in the material’s thermal properties. According to a study by Plastics Technology, nearly 60% of production defects can be attributed to inadequate material selection based on temperature resistance. Using materials that have low thermal stability can result in warping and dimensional inaccuracies, ultimately affecting the final product's quality.

Another critical factor is the material’s compatibility and flow characteristics. The American Society of Mechanical Engineers reports that optimizing flow properties greatly reduces the likelihood of defects such as short shots and sink marks. For instance, when selecting materials with high viscosity for complex geometries, processors often encounter challenges in achieving uniform filling, leading to subpar products. Additionally, the selection of fillers or additives can influence the mechanical performance and processing behavior of resins. Therefore, careful consideration of these factors can significantly enhance the efficiency and effectiveness of the injection molding process, resulting in higher yields and reduced scrap rates.

Common Challenges Faced in Mold Plastic Injection Processes

This chart illustrates the common challenges encountered in plastic injection molding processes due to material selection.

Design Flaws and Their Impact: 3 Common Design Challenges in Mold Manufacturing Processes

In the realm of mold plastic injection processes, design flaws can significantly hinder both production efficiency and product quality. One of the primary challenges arises from inadequate design specifications, leading to molds that do not align with the intended product requirements. This misalignment can cause issues such as imbalance in material flow, resulting in uneven filling of the mold cavity. Consequently, manufacturers may face increased scrap rates and rework, both of which negatively impact productivity and cost-effectiveness.

Another common design challenge is the failure to incorporate proper draft angles in the mold. Without sufficient draft, parts can become stuck in the mold, leading to potential damage during ejection. This not only prolongs cycle times but also poses a risk of damaging the plastic components themselves, thereby compromising the integrity of the final product. Additionally, poor cooling channel design can lead to overheating and warping, further complicating production and increasing turnaround times. Addressing these design considerations early in the manufacturing process is crucial for optimizing the injection molding operation and ensuring high-quality output.

Related Posts

-

Understanding Characteristics and Applications of Best Injection Molding Tooling Variants

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry

-

Quality Driven Global Success of Prototype Injection Molding from China

-

5 Key Benefits of Investing in Injection Tooling for Global Buyers

-

Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

-

Creative Examples of Successful Injection Molding Applications Across Industries