Understanding Characteristics and Applications of Best Injection Molding Tooling Variants

The injection molding tooling industry plays a pivotal role in manufacturing, providing versatile solutions for producing a wide array of plastic components across various sectors. According to the Global Injection Molding Market Report, the global market for injection molding is projected to reach approximately $300 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 4.2%. This growth is attributable to the increasing demand for lightweight and complex components in automotive, consumer electronics, and healthcare industries.

Understanding the characteristics and applications of the best injection molding tooling variants is crucial for manufacturers looking to optimize production efficiency and product quality. This blog will delve into the technical specifications of different tooling options and offer practical insights on their applications, ultimately guiding stakeholders in selecting the right tooling solutions for their specific needs.

The injection molding tooling industry plays a pivotal role in manufacturing, providing versatile solutions for producing a wide array of plastic components across various sectors. According to the Global Injection Molding Market Report, the global market for injection molding is projected to reach approximately $300 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 4.2%. This growth is attributable to the increasing demand for lightweight and complex components in automotive, consumer electronics, and healthcare industries.

Understanding the characteristics and applications of the best injection molding tooling variants is crucial for manufacturers looking to optimize production efficiency and product quality. This blog will delve into the technical specifications of different tooling options and offer practical insights on their applications, ultimately guiding stakeholders in selecting the right tooling solutions for their specific needs.

Key Features of Injection Molding Tooling for Enhanced Production Efficiency

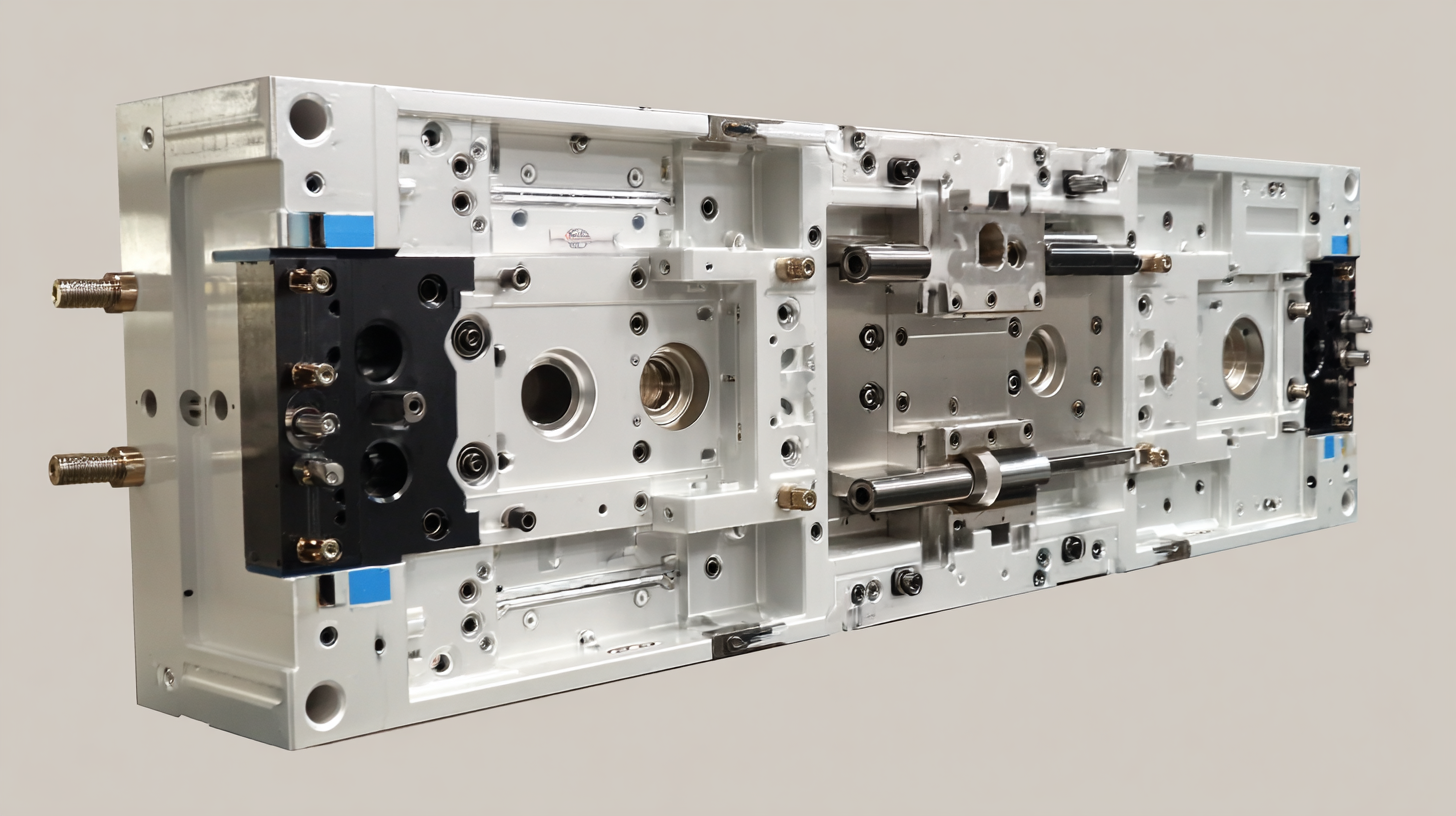

Injection molding tooling plays a crucial role in the manufacturing process, significantly impacting production efficiency. Understanding the key features of these tools can help companies optimize their operations, reduce costs, and increase throughput. One of the primary characteristics is the material used for tooling, with options ranging from aluminum for low-volume runs to steel for higher durability and longevity in mass production. Selecting the right material can greatly influence both performance and production speed.

Tips: When choosing tooling materials, consider the production volume and the complexity of the parts. For low-volume projects, aluminum tooling can be a cost-effective option, while advanced steel options are more suitable for high-volume needs.

Another important aspect is the design of the tooling, particularly regarding cooling channels and gate locations. Efficient cooling systems can drastically reduce cycle times and improve overall efficiency. Optimizing the flow of molten plastic with strategically placed gates and cooling channels can help ensure uniform filling and reduce defects.

Tips: Utilize simulation software to analyze and refine tooling designs before production. This proactive approach can highlight potential issues and lead to more efficient designs that enhance production efficiency.

Innovative Materials Used in Top-Quality Injection Molding Tooling

The evolution of injection molding tooling has significantly benefited from the incorporation of innovative materials, enhancing both performance and efficiency. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach USD 284.84 billion by 2026, with advanced tooling materials playing a pivotal role in this growth. High-performance polymers, such as PEEK and PEI, are now preferred choices due to their high thermal stability and chemical resistance, which are critical for producing complex and durable components.

Moreover, metal alloys and composites have emerged as vital alternatives, offering superior strength-to-weight ratios and improved wear resistance. A study published by the American Society for Testing and Materials (ASTM) highlights that materials like titanium and aluminum alloys not only enhance tooling life but also reduce production costs in the long run. As manufacturers increasingly adopt these advanced materials, they are able to optimize the injection molding process, resulting in higher efficiency and better quality outputs across various industries, from automotive to consumer electronics.

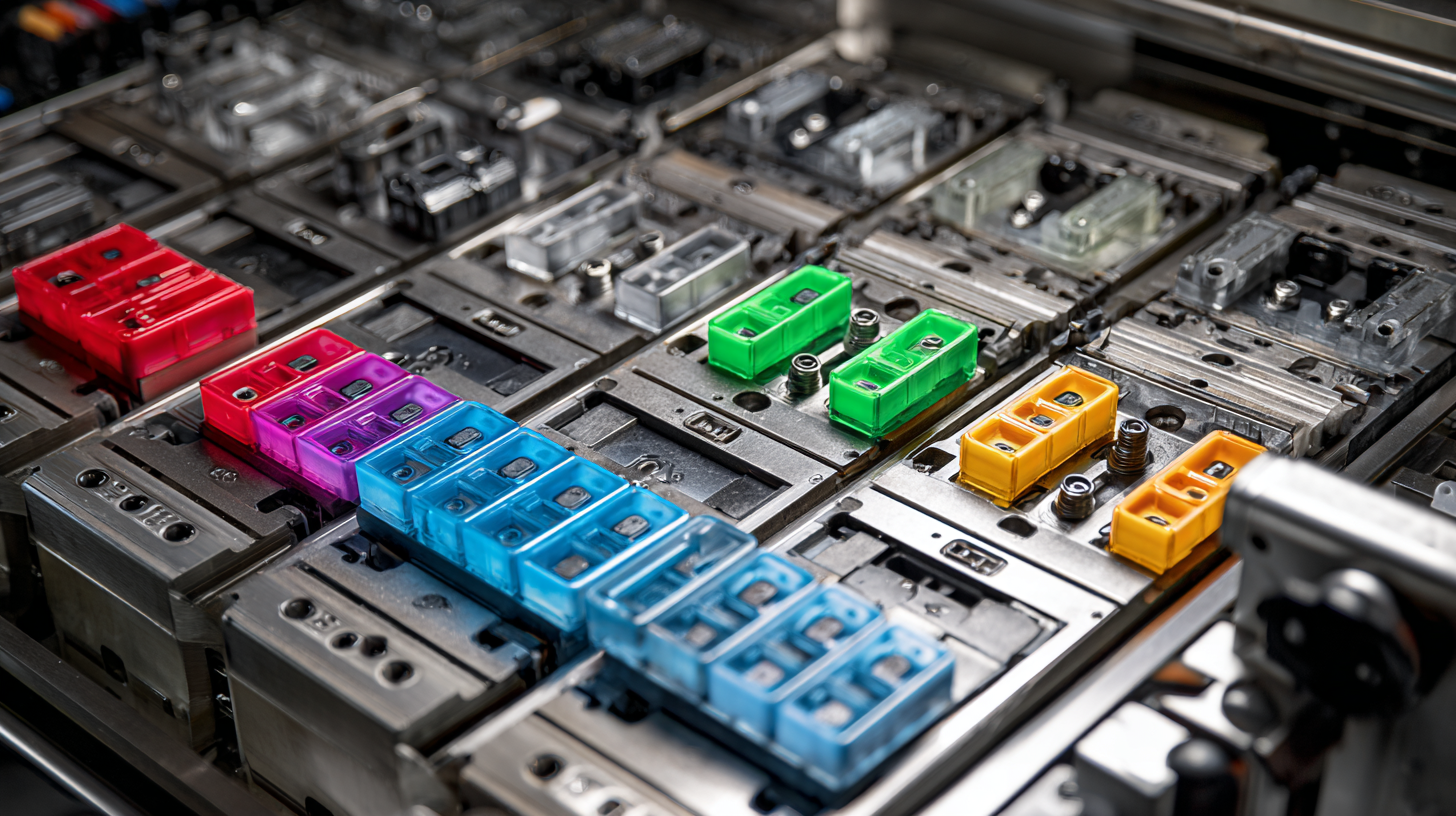

Comparative Analysis of Injection Molding Tooling Variants and Their Applications

When exploring injection molding tooling variants, it's crucial to conduct a comparative analysis to determine which type best meets specific production needs. Key variants include single-cavity molds, multi-cavity molds, and family molds. Single-cavity molds are ideal for low-volume production and prototyping, offering simplicity and lower upfront costs. In contrast, multi-cavity molds significantly increase efficiency by producing multiple parts in one cycle, making them suitable for high-volume runs. Family molds can produce different parts simultaneously, maximizing material use and reducing cycle times, although they may require more meticulous design work.

Tip: When selecting a tooling variant, consider both the production volume and the specificity of the parts being produced. This will help in balancing initial costs with operational efficiency. Additionally, collaborating closely with your molding partner can provide insights that streamline the design process.

Another notable option is the use of cold runner versus hot runner systems. Cold runners are typically less expensive and easier to maintain; however, they can result in greater material waste. Hot runner systems, while more costly, offer enhanced efficiency by minimizing waste and improving cycle times. Evaluating these systems according to your project scale and budget can lead to significant cost savings in the long run.

Tip: Always factor in the recovery and recycling of materials when choosing your injection molding tooling. This not only helps in reducing costs but also enhances the sustainability of your manufacturing process.

Quality Control Practices in Leading Chinese Factories for Molding Tools

Quality control practices in injection molding are crucial, especially in the context of leading Chinese factories, where the industry is witnessing rapid growth. As highlighted by recent market projections, the industrial mold market is expected to reach USD 68.3 billion by 2032, demonstrating a remarkable compound annual growth rate (CAGR) of 11.2%. This growth underscores the importance of stringent quality control measures to ensure that production outputs consistently meet high standards, preventing issues such as contamination commonly reported in other industries.

Recent FDA warnings about the compliance violations of foreign drug manufacturers, including mold and unhygienic conditions, serve as a stark reminder of the critical need for quality assurance in manufacturing processes. For plastic injection molding tools, quality control encompasses rigorous inspections and adherence to GMP (Good Manufacturing Practices) to avert risks that could lead to defective products. Facilities engaging in best practices not only enhance their reputation but also improve operational efficiency, which is essential as the demand for intelligent injection molding technologies continues to rise. With innovations focusing on sensing, optimization, and control, those factories prioritizing quality will undoubtedly lead in the evolving manufacturing landscape.

Future Trends in Injection Molding Tooling and Their Global Impact

The future of injection molding tooling is poised for significant transformation, driven by advancements in technology and evolving market demands. According to a recent report by Allied Market Research, the global injection molding market is expected to reach $342 billion by 2027, growing at a CAGR of 5.2%. This growth underscores the need for more efficient tooling solutions that can adapt to shorter production cycles and the rising complexity of designs. Innovations such as 3D printing and advanced materials are enabling manufacturers to create lightweight, durable molds that can withstand the rigors of high-volume production while minimizing waste.

Moreover, the integration of Industry 4.0 technologies is enhancing the precision and efficiency of injection molding processes. Implementation of IoT-enabled machinery allows for real-time monitoring and predictive maintenance, thus reducing downtime and operational costs. A study by Grand View Research predicts that the smart manufacturing market, including injection molding, will reach $507 billion by 2025, indicating a clear trend towards automation and data-driven decision-making. As these technologies continue to evolve, their global impact will reshape not only production capabilities but also the overall supply chain dynamics, paving the way for more sustainable manufacturing practices.