How to Choose the Right Injection Molding Tooling for Your Production Needs

In the dynamic landscape of manufacturing, selecting the appropriate injection molding tooling is crucial for optimizing production efficiency and ensuring product quality. According to a study by Grand View Research, the global injection molding market is projected to reach USD 346.67 billion by 2025, underscoring the growing demand for precision-engineered components across various industries, including automotive, consumer goods, and medical devices. The right tooling can significantly impact cycle times, production costs, and overall output. Research indicates that nearly 30% of production delays stem from inadequate tooling choices, highlighting the importance of making informed decisions. By understanding the key factors that influence injection molding tooling, manufacturers can enhance their operational performance and maintain a competitive edge in the marketplace.

Understanding Your Production Volume and Requirements

When selecting the right injection molding tooling for your production needs, it's crucial to understand your production volume and specific requirements. Production volume greatly influences the choice of tooling, as different volumes demand distinct approaches for manufacturing efficiency.

For lower production volumes, using tooling with simpler designs and quicker turnaround times can streamline the initial process. Conversely, for high-volume production, investing in more durable, complex tooling can reduce per-unit costs over time, benefiting from economies of scale.

Additionally, consider the nature of the products you intend to produce. Products that require intricate details or tight tolerances will necessitate advanced tooling that can maintain precision across numerous cycles. Analyzing your market demand and understanding seasonal fluctuations in production can also aid in aligning your tooling choices with business needs. By carefully assessing these variables, you can select tooling that not only meets your current requirements but is also adaptable for future production goals.

This foresight can have lasting impacts on your operational efficiency and cost-effectiveness in the competitive manufacturing landscape.

Evaluating Different Types of Injection Molding Tools

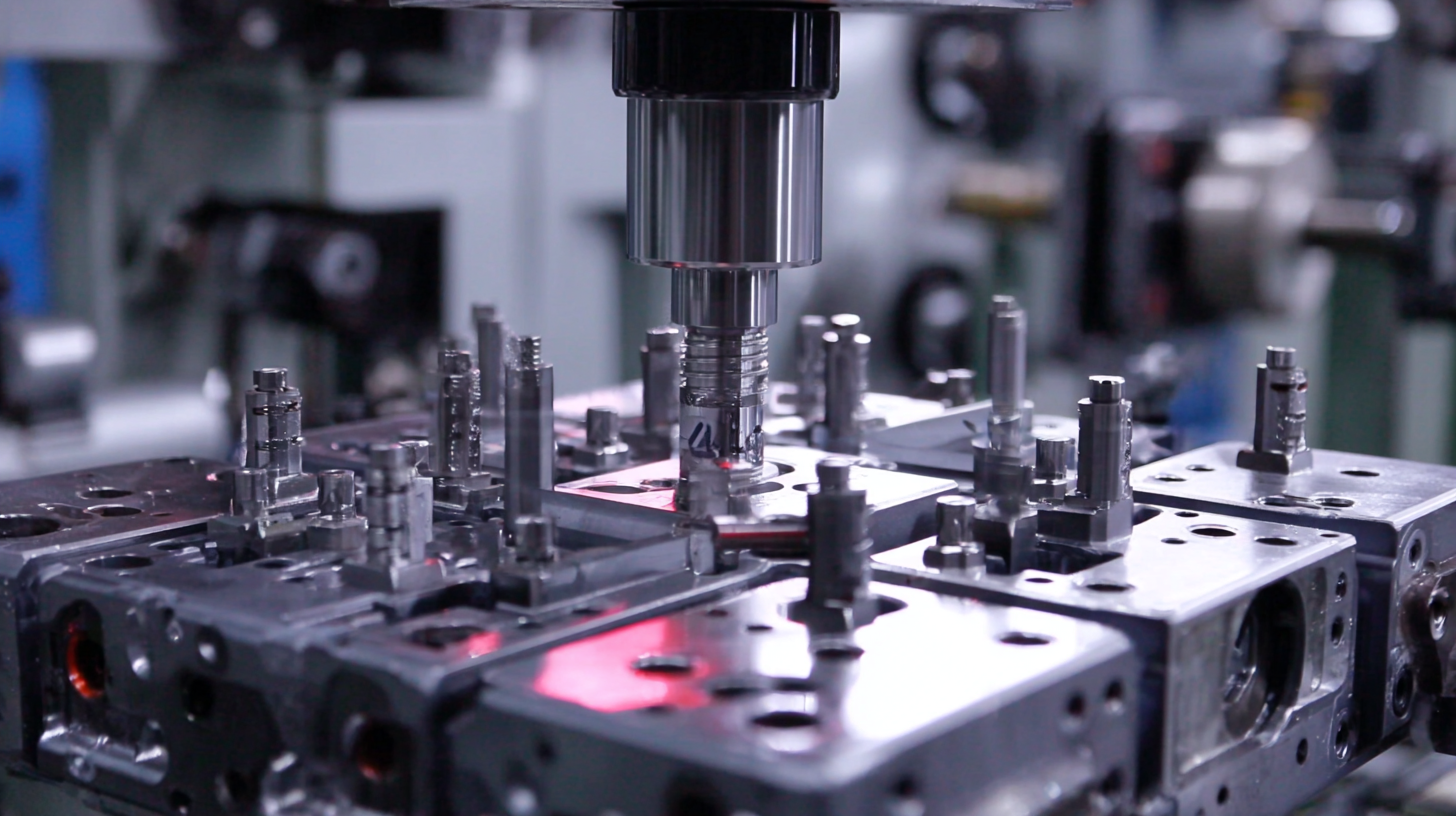

When it comes to injection molding, selecting the right tooling is crucial for optimizing production efficiency and maintaining quality standards. Different types of injection molding tools are available, each tailored to specific manufacturing applications. For instance, standard molds are ideal for high-volume production runs, offering durability and consistent output. Conversely, prototype molds serve well in the product development phase, allowing for quicker alterations to design and functionality without the higher costs associated with full production tools.

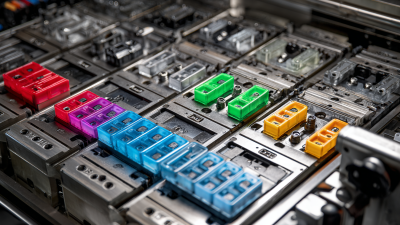

Additionally, there are specialized molds, such as multi-cavity molds and family molds, which are designed to produce multiple parts in a single cycle. Multi-cavity molds increase productivity by creating several identical parts simultaneously, while family molds can produce different parts that share a common runner system. Understanding the nuances between these tooling types can significantly affect production timelines and costs, making it essential for manufacturers to assess their specific needs, volume requirements, and budget constraints to select the most suitable injection molding tools.

Comparative Analysis of Different Injection Molding Tools

This chart provides a comparative cost estimate for different types of injection molding tools commonly used in production. Understanding the cost implications can assist in making informed decisions for tooling choices based on specific production needs.

Assessing Material Compatibility for Optimal Tool Performance

When selecting injection molding tooling, material compatibility plays a critical role in ensuring optimal tool performance. Different materials have unique properties that can significantly influence how they interact with molds during the injection process. Understanding the thermal, chemical, and mechanical characteristics of your chosen material is essential for ensuring that your tooling is both effective and durable.

Tip 1: Always consult with your material supplier to gain insights into compatibility with specific mold materials and coatings. This can help you avoid issues related to wear and tear, as well as reduce the risk of defects in the final product.

Additionally, consider the processing temperatures and flow rates of your materials. High-temperature resins may require specialized steel molds to withstand the heat, while certain plastics might adhere to mold surfaces, leading to difficulties in demolding.

Tip 2: It’s beneficial to conduct trial runs using your selected materials to observe how they behave under real production conditions. This hands-on approach can highlight any potential problems early in the process, allowing for adjustments to be made before full-scale production begins.

Cost Considerations: Balancing Quality and Budget

When selecting injection molding tooling, cost considerations play a crucial role in balancing quality and budget. According to a report by Grand View Research, the global injection molding market is projected to reach $341.5 billion by 2027, underscoring the importance of careful financial planning in tooling decisions. High-quality molds can range from $5,000 to upwards of $100,000, depending largely on the complexity of the part and material choice. Therefore, companies must evaluate their production volumes and material requirements to avoid over-investing in tooling that may not meet their needs.

Tips: To manage costs effectively, consider starting with prototyping techniques such as 3D printing to refine designs before committing to expensive tooling. Additionally, collaborating with a reputable tooling manufacturer can provide insights into cost-saving innovations that do not compromise quality. Regularly assessing your production and market demand can help you adjust your tooling investments, ensuring you get optimal returns without exceeding your budget.

Balancing quality and budget also involves understanding the implications of tooling material. Steel molds, while more costly, offer durability for high-volume production, while aluminum molds are less expensive and suited for low-volume runs. Investing in the right material based on long-term production goals can greatly impact overall cost efficiency.

Choosing the Right Manufacturer for Your Tooling Needs

When it comes to selecting the right manufacturer for your injection molding tooling, understanding the nuances of quality and reliability is paramount. According to a recent report from MarketsandMarkets, the global injection molding market is expected to reach over $300 billion by 2025, underscoring the importance of choosing a trustworthy supplier who can meet escalating production demands. A reputable manufacturer not only provides high-quality tooling but also offers expertise in material selection and design optimization, which can significantly impact the efficiency and cost-effectiveness of the production process.

Additionally, evaluating a manufacturer’s technological capabilities is crucial. As stated in a 2022 survey by Plastics News, 78% of industry professionals identified advanced tooling technologies, such as the use of CAD/CAM software and 3D printing, as key factors that enhance production accuracy and reduce lead times. By partnering with a manufacturer that embraces these innovations, businesses can better navigate the complexities of modern production, ensuring that their tooling is not only robust but also adaptable to future needs. The right manufacturer can be a game-changer, turning production visions into reality seamlessly.

Related Posts

-

Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

-

Common Challenges Faced in Mold Plastic Injection Processes

-

Understanding Characteristics and Applications of Best Injection Molding Tooling Variants

-

5 Key Benefits of Investing in Injection Tooling for Global Buyers

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

The Future of Injection Tooling Innovations and Opportunities