Top 10 Essential Factors to Consider for Injection Molding Mold in 2025

In the rapidly evolving landscape of manufacturing, the significance of an efficient and well-designed injection molding mold cannot be overstated. As we approach 2025, industry experts stress the need for forward-thinking strategies to enhance production capabilities while ensuring sustainability and cost-effectiveness. Dr. Emily Carter, a leading authority in injection molding technologies, emphasizes, "The success of any injection molding process hinges on the design and quality of the mold. Innovating in this area can unlock unparalleled efficiencies."

As companies strive to stay competitive, understanding the essential factors that influence injection molding mold development will be paramount. From material selection to cooling systems, each component plays a critical role in the overall performance and reliability of the mold. Furthermore, with advancements in technology and shifts in consumer demand, manufacturers must adapt their practices to align with current trends and future needs.

In this context, we will explore the top ten essential factors to consider for injection molding molds in 2025, aimed at guiding engineers and manufacturers in making informed decisions that will shape the future of production processes. With a strategic focus on these elements, the potential for innovation and efficiency in the injection molding industry is immense.

Key Material Selection Criteria for Injection Molding in 2025

In 2025, the selection of materials for injection molding is more crucial than ever, with an increasing focus on sustainability, performance, and cost-effectiveness. When choosing the right materials, factors such as compatibility with the manufacturing process, mechanical properties, and environmental impact must be thoroughly evaluated. Not only do the materials need to meet the specific physical and chemical requirements of the final product, but they should also align with the industry standards for safety and sustainability. This balance is becoming essential as businesses face growing consumer demand for environmentally friendly products.

**Tips:** When assessing materials for injection molding, consider utilizing simulation software that allows you to test the flow and cooling characteristics of different materials before committing to a choice. Additionally, involving suppliers early in the process can provide insight into the availability of materials and potential challenges during production.

Another critical factor is the material's ability to withstand the intended application conditions, including temperature, humidity, and chemical exposure. It’s advisable to conduct thorough testing and validation of the materials under operational conditions to ensure longevity and performance. As the industry evolves, innovations in alternative materials, like bio-based or recycled plastics, will provide new opportunities for injection molders looking to enhance their product offerings while reducing environmental impact.

**Tips:** Stay updated on emerging materials and innovations by attending industry conferences and workshops. Networking with peers can also lead to valuable insights into material performance and best practices in the industry.

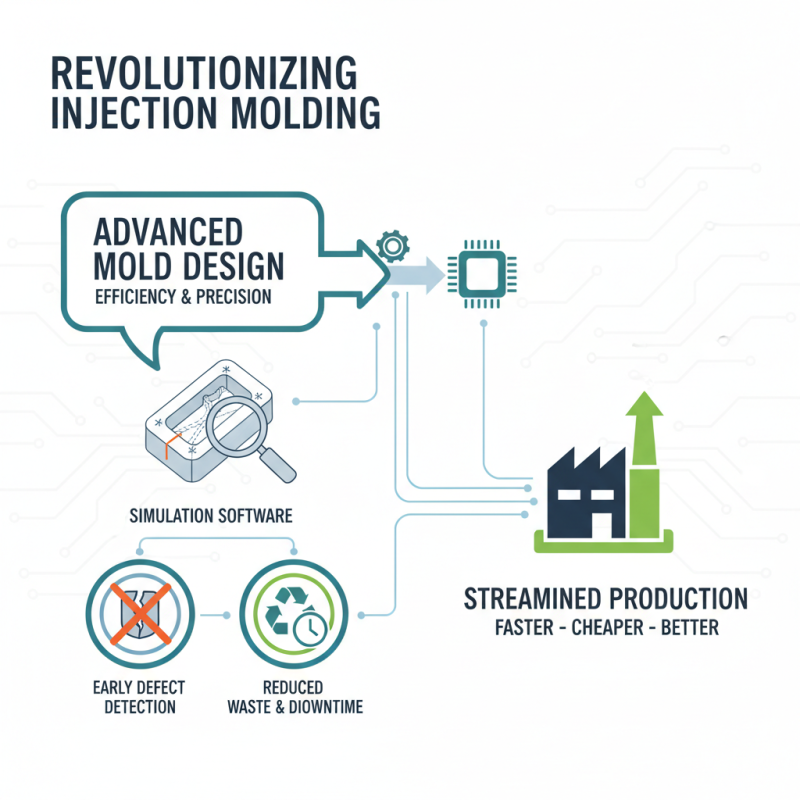

Advanced Mold Design Techniques Enhancing Efficiency and Precision

Advanced mold design techniques are revolutionizing the injection molding industry, enhancing both efficiency and precision in manufacturing processes. One critical aspect of contemporary mold design is the integration of advanced simulation software. This technology allows engineers to create detailed virtual models of molds, enabling them to predict and resolve potential issues before production begins. By identifying all possible defect scenarios early on, manufacturers can significantly reduce material waste and downtime, ultimately streamlining the entire production process.

In addition to simulation software, the use of advanced materials plays a vital role in mold design. New composite materials and coatings can improve the durability and thermal management of molds, leading to better performance under varying operational conditions. This is particularly important as the demand for higher precision and longer-lasting products grows. Furthermore, innovations such as additive manufacturing allow for the creation of complex geometries that were previously difficult, if not impossible, to achieve. These advancements not only enhance mold efficiency but also enable the production of intricate designs that meet the evolving needs of the market.

Automation and Smart Technologies in Injection Molding Processes

The injection molding industry is experiencing a transformative phase driven by automation and smart technologies. In 2025, integrating these innovations will redefine production efficiency and product quality. Automation technologies, like robotics and AI, streamline repetitive tasks, reduce human error, and significantly enhance precision in molding processes. By enabling real-time monitoring, manufacturers can adjust parameters on-the-fly to adapt to varying conditions, ensuring optimal performance.

Tips for implementing automation in injection molding:

- Invest in training: Ensure your workforce is well-trained in operating automated systems for seamless transitions and maximum productivity.

- Embrace data analytics: Utilize smart technologies to gather and analyze data from the molding process. This insight can lead to improved decision-making and predictive maintenance.

Moreover, smart technologies such as IoT sensors are crucial for remote monitoring and management of equipment. These sensors can detect potential issues before they escalate, saving downtime and costly repairs. With predictive analytics, manufacturers can foresee trends in production, allowing for better planning and resource allocation.

Tips for leveraging smart technologies:

- Choose scalable solutions: Opt for technologies that can grow with your business needs and adapt to new trends in the industry.

- Foster collaboration: Encourage teamwork between IT and production departments to maximize the benefits of technology integration.

Focusing on automation and smart technologies will not only elevate the efficiency of injection molding processes but also position companies to stay ahead in an increasingly competitive landscape.

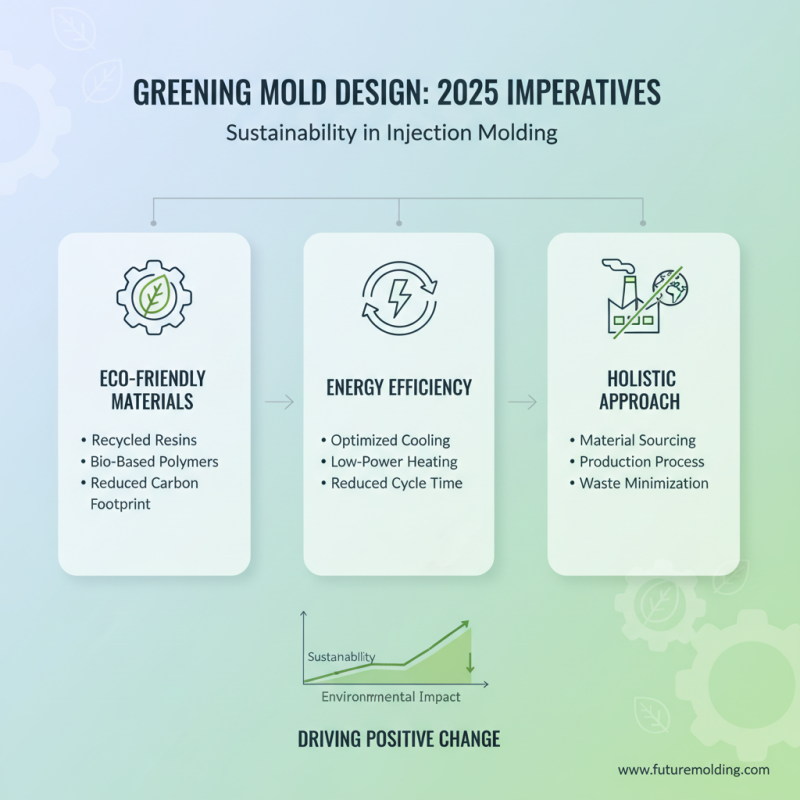

Sustainability Practices Impacting Mold Design and Production Costs

As sustainability becomes increasingly vital in industrial practices, its influence on mold design in injection molding cannot be overlooked. In 2025, manufacturers are expected to prioritize eco-friendly materials and processes to minimize their environmental impact. This shift towards sustainability compels mold designers to consider not just the functionality and efficiency of the mold but also the sourcing of materials and the energy consumed during production. For instance, using recycled or bio-based resins can significantly reduce carbon footprints, leading to a transition toward more sustainable mold designs.

Moreover, cost implications of sustainable practices in mold production are becoming a crucial factor. While initial investments may be higher for sustainable materials and technology, the long-term benefits often outweigh these costs. Efficiency in production methods, such as energy-efficient machinery and waste reduction strategies, can ultimately lead to lower operational costs. As companies seek to align their practices with environmentally conscious goals, the integration of sustainability into mold design will not only enhance competitive advantage but also fulfill increasingly stringent regulatory and consumer demands for responsible manufacturing. Ultimately, the balance between sustainability and cost-effectiveness will shape the future of injection molding in ways that prioritize both ecological responsibility and business viability.

Regulatory Compliance and Safety Standards for Injection Molding Molds

In the world of injection molding, regulatory compliance and safety standards are paramount. As manufacturers and designers expand their operations in 2025, being well-versed in the latest regulations will be essential. These standards provide a framework that ensures both the quality of the molds produced and the safety of the processes employed. Compliance with safety regulations not only mitigates the risk of accidents in the workplace but also protects the integrity of the end products that emerge from these molds.

Moreover, understanding the evolving landscape of environmental regulations is crucial for sustainability. Many regions are implementing stricter guidelines on materials used and waste management practices, compelling manufacturers to adapt. By proactively integrating these compliance measures into the design and production phases, companies can not only ensure adherence to regulations but can also promote a culture of safety and responsibility. As such, investing in training and staying updated on the latest compliance requirements will be a critical factor in maintaining a competitive edge in the injection molding industry.

Related Posts

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

The Future of Injection Tooling Innovations and Opportunities

-

How to Choose the Right Injection Molding Tooling for Your Production Needs

-

Understanding the Essential Role of Injection Molding Tooling in Modern Manufacturing

-

Understanding the Injection Moulding Process Innovations and Applications in Modern Manufacturing

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry