Top Benefits of the Injection Moulding Process for Manufacturing Success

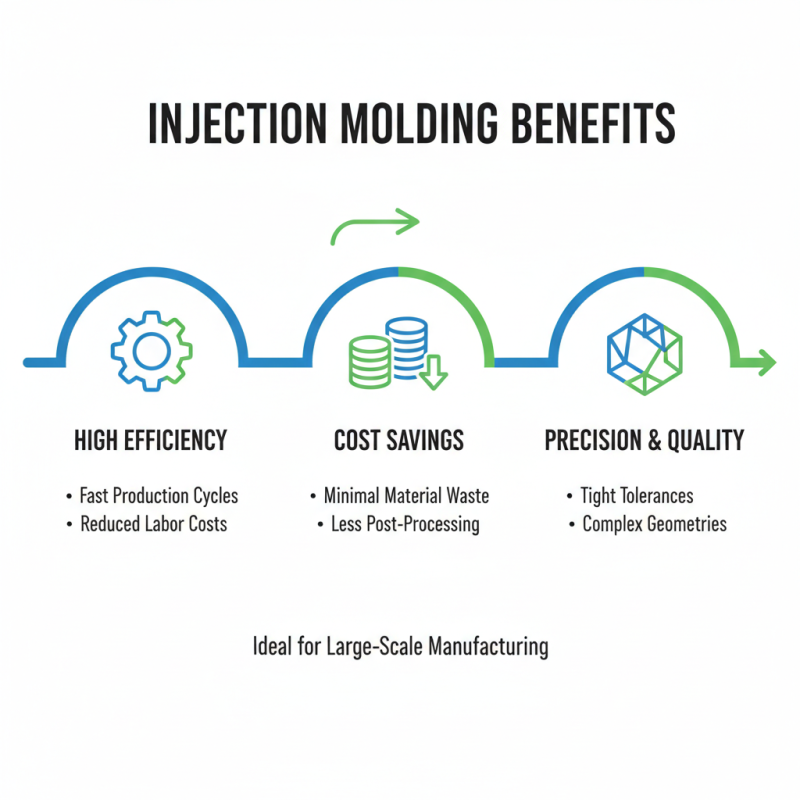

The injection moulding process has become a cornerstone in the realm of manufacturing, offering numerous advantages that propel businesses toward success. According to industry expert Dr. Emily Walton, a leading authority in plastics engineering, “The injection moulding process not only enhances production efficiency but also ensures unmatched precision and consistency in the final products.” As manufacturers strive to meet the growing demand for high-quality products at competitive prices, understanding the benefits of this innovative process is crucial.

This advanced technique allows for rapid production of complex shapes with minimal waste, making it an environmentally friendly option, as well. With increasing pressures for sustainability and cost-effectiveness, companies are recognizing the injection moulding process as a viable solution that aligns with their operational goals. As we delve deeper into the top benefits of the injection moulding process, it becomes clear how this method is transforming the landscape of manufacturing and setting the stage for future innovations in the industry.

Overview of Injection Moulding Process in Manufacturing

Injection moulding is a highly efficient and versatile manufacturing process that is widely used in the production of plastic parts. The process begins with the melting of plastic pellets, which are then injected into a precisely designed mould where they cool and solidify into the final product. This technique not only allows for intricate designs and shapes to be produced with high precision, but it also facilitates mass production, making it a cost-effective choice for manufacturers.

The advantages of injection moulding extend beyond just its efficiency. It enables rapid production cycles, which is crucial in meeting market demands quickly. Additionally, the consistency in part quality is a significant benefit, as the automated nature of the process ensures uniformity across large batches. Manufacturers can also utilize a wide range of materials, including various types of thermoplastics and thermosetting plastics, offering flexibility in product development. Overall, the injection moulding process stands out as a key driver for manufacturing success, enabling companies to innovate and respond swiftly to consumer needs.

Top Benefits of the Injection Moulding Process for Manufacturing Success

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| High Efficiency | Injection moulding allows for rapid production cycles, enabling manufacturers to produce large quantities quickly. | Increased output, leading to lower cost per unit. |

| Design Flexibility | Complex geometries and precise dimensions can be achieved, allowing for innovative designs. | Enhanced product offerings and competitiveness in the market. |

| Material Versatility | Wide range of materials can be used, including various plastics and elastomers tailored for specific applications. | Broader application across multiple industries. |

| Reduced Waste | The injection process minimizes excess material, reducing scrap rates. | Lower material costs and improved sustainability practices. |

| Automated Production | Injection moulding can be easily automated, leading to consistent quality and efficiency. | Decreased labor costs and minimized human error. |

Key Advantages of Injection Moulding for Mass Production

Injection moulding has become a cornerstone of mass production due to its numerous advantages. One key benefit is its ability to produce high volumes of identical parts with great precision. This consistency not only reduces waste but also ensures that quality control measures can be effectively implemented throughout the manufacturing process. For companies looking to scale their production, injection moulding offers a robust solution that optimizes efficiency and increases output.

Tip: To further enhance the effectiveness of injection moulding, consider investing in advanced mould design and simulation software. This can help identify potential issues early in the design phase, thus saving time and costs during production.

Another significant advantage of injection moulding is its versatility with materials. Manufacturers can utilize a range of thermoplastics and thermosetting polymers, allowing for customization based on the specific needs of the product. This flexibility supports the creation of complex shapes and features that other manufacturing processes might struggle to achieve.

Tip: When selecting materials for injection moulding, always evaluate the end-use requirements of the product, such as strength, temperature resistance, and flexibility, to ensure optimal performance.

Top Benefits of the Injection Moulding Process for Manufacturing Success

Cost Efficiency and Material Utilization in Injection Moulding

Injection moulding is a highly efficient manufacturing process that significantly enhances cost efficiency and material utilization. By using this method, manufacturers can produce high volumes of parts with minimal waste, making it an attractive option for large-scale production. The precision of injection moulding allows for the creation of complex shapes with tight tolerances, reducing the need for additional machining and lowering overall production costs.

**Tips:** To maximize cost efficiency, it is essential to consider the design of the parts early in the development stage. Opt for designs that minimize material usage while maintaining strength and functionality. Additionally, utilizing simulations to optimize the mould design can further enhance material utilization and reduce cycle times.

Moreover, injection moulding benefits from economies of scale. As production volume increases, the cost per unit decreases, making it ideal for manufacturers looking to maintain competitive pricing. By carefully selecting materials that can be reused or recycled, companies can also contribute to sustainability efforts while keeping production costs in check.

**Tips:** Regularly review your material inventory to make informed decisions about purchasing and recycling options. Implementing a robust waste management system can also lead to significant savings over time.

Design Flexibility and Product Customization in Injection Moulding

The injection moulding process offers unparalleled design flexibility and product customization, making it a cornerstone for manufacturing success. This technique allows for intricate detailing and complex geometries that are often required in modern product designs. With the ability to create a diverse range of shapes and sizes, manufacturers can meet specific customer demands and preferences, enhancing both functionality and aesthetic appeal.

Furthermore, the adaptability of injection moulding supports the rapid integration of new materials and innovative designs. As industry demands evolve, companies leveraging this process can quickly adjust their production lines to incorporate changes without significant downtime. This responsiveness not only positions manufacturers to stay competitive but also cultivates a reputation for quality and innovation in the marketplace. Thus, the synergistic benefits of flexibility and customization play a crucial role in driving manufacturing success across various sectors.

Quality and Precision in Components Produced by Injection Moulding

Injection moulding is a cornerstone of modern manufacturing, renowned for producing high-quality and precise components across diverse industries. According to a report by the Plastics Industry Association, around 29% of all plastics manufactured globally are processed through injection moulding, highlighting its pivotal role. This process not only delivers consistency but also allows for intricate designs that meet stringent specifications. The tolerance levels achievable, often within ±0.1mm, make injection moulding ideal for applications requiring exacting standards, such as in the automotive and medical sectors.

Tip: When selecting materials for injection moulding, consider their thermal stability and strength. High-performance polymers, such as polycarbonate or nylon, are excellent for parts exposed to tough conditions, ensuring durability and efficiency.

Precision does not end with the materials; it extends to the machinery utilized. Advanced injection moulding machines with real-time monitoring systems contribute to maintaining quality control throughout production. This capability allows manufacturers to respond quickly to variations in process parameters, resulting in fewer defects and waste.

Tip: Invest in training operators on the latest moulding technologies and techniques to enhance precision and reduce downtime, ultimately contributing to overall manufacturing success.

Related Posts

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry

-

Quality Driven Global Success of Prototype Injection Molding from China

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

Exploring Innovative Alternatives to Injection Moldable Plastics for Sustainable Production

-

7 Reasons Why Short Run Injection Molding is the Best Choice for Your Business

-

The Future of Injection Tooling Innovations and Opportunities