10 Key Advantages of Using Plastic Injection Molded Parts in Manufacturing

In the ever-evolving landscape of manufacturing, the choice of materials and production methods plays a pivotal role in determining both efficiency and product quality. One prominent technique that has gained substantial traction is the use of plastic injection molded parts. This method not only streamlines the production process but also offers a myriad of advantages that can significantly enhance the overall manufacturing experience. From cost-effectiveness to design versatility, plastic injection molded parts provide manufacturers with the capability to produce complex shapes while maintaining tight tolerances. Additionally, the durability and lightweight nature of these components make them ideal for a wide range of applications across various industries. In this article, we will explore ten key advantages of incorporating plastic injection molded parts into production processes, highlighting why this manufacturing approach is increasingly becoming the preferred choice for businesses aiming to optimize performance and foster innovation.

Understanding the Basics of Plastic Injection Molding in Manufacturing

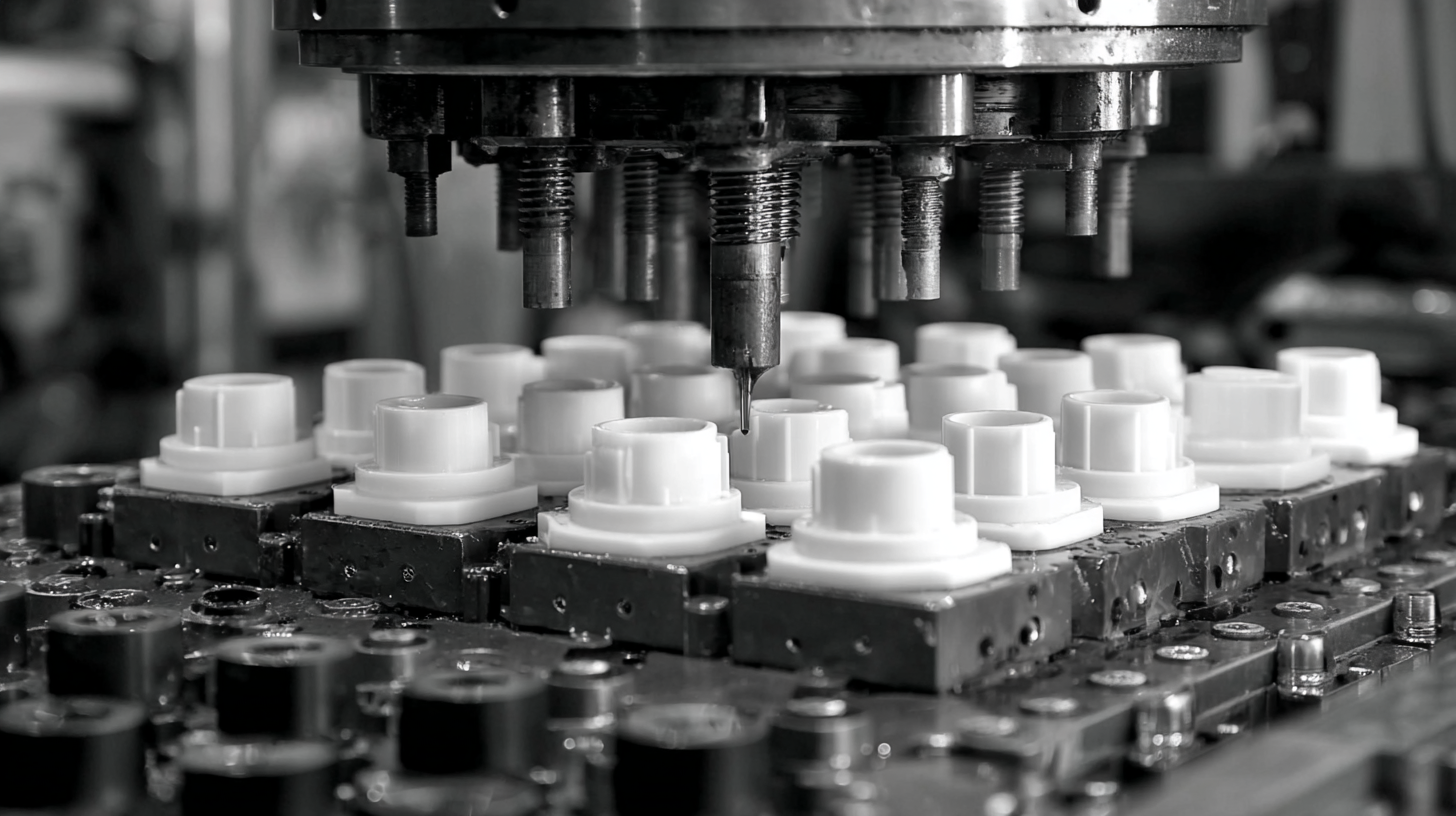

Plastic injection molding is a highly efficient and versatile manufacturing process that involves creating parts by injecting molten plastic into a mold. This method allows for the mass production of complex shapes with high precision and consistency. The process begins with heating plastic pellets until they melt, after which they are injected into a pre-designed mold under high pressure. Once cooled, the mold is opened, and the finished part is ejected. This technique is instrumental in various industries, including automotive, electronics, and consumer goods, owing to its ability to produce durable and lightweight components.

One of the key benefits of plastic injection molding is its scalability. Manufacturers can produce large quantities of the same part quickly and at a lower cost per unit compared to other methods. Additionally, the use of automated machinery reduces labor costs and minimizes human error. Moreover, the flexibility of design offered by injection molding allows for modifications and adjustments without significant downtime, making it an advantageous choice for companies looking to innovate or modify their product lines. Overall, understanding the basics of plastic injection molding helps manufacturers leverage its advantages to enhance efficiency and production quality.

10 Key Advantages of Using Plastic Injection Molded Parts in Manufacturing

| Advantage | Description |

|---|---|

| High Efficiency | Plastic injection molding allows for fast production cycles and high output rates, making it ideal for mass production. |

| Cost-Effectiveness | The process reduces labor costs and material waste, leading to lower overall production costs. |

| Design Flexibility | Complex designs can be achieved with high precision, allowing for intricate details and shapes. |

| Material Versatility | A wide range of plastic materials can be used, each offering different properties to meet specific application needs. |

| Consistency and Quality | Injection molding provides consistent quality with minimal variation between parts. |

| Reduced Waste | The process utilizes only the necessary amount of material, significantly reducing scrap compared to other methods. |

| Quick Prototyping | Prototypes can be produced quickly, allowing for rapid testing and design iterations. |

| Complex Geometries | The technique supports manufacturing of parts with complex geometries that would be difficult to achieve with other methods. |

| Automation Friendly | The injection molding process can be easily automated, increasing production efficiency. |

| Minimum Post-Processing | Finished parts often require little to no additional processing, saving time and cost. |

Cost-Effectiveness: How Plastic Injection Molded Parts Reduce Production Expenses

In the realm of manufacturing, cost-effectiveness is crucial, and plastic injection molded parts have emerged as a game-changer. According to a report by Grand View Research, the global plastic injection molding market is expected to reach USD 439.22 billion by 2025, driven largely by the advantages these parts offer in terms of production efficiency and cost reduction. By using high-volume production, companies can achieve economies of scale that significantly lower the cost per part, making it an attractive option for businesses looking to maximize profits while maintaining quality.

When considering plastic injection molding, it's essential to focus on material selection and design optimization. Choosing the right resin can enhance durability and reduce waste, contributing to overall cost savings. Moreover, incorporating design for manufacturability (DFM) principles will streamline the production process, minimizing both time and resources.

Tip: Always conduct a thorough cost analysis before transitioning to plastic injection molding, as this will help identify potential savings and ensure that the investment aligns with your manufacturing goals. Additionally, collaborating with a skilled supplier can provide valuable insights into the best practices for reducing costs while optimizing production efficiency.

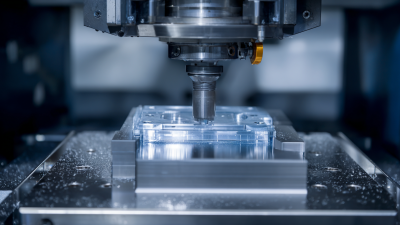

Enhancing Design Flexibility with Injection Molded Plastic Components

Plastic injection molding has revolutionized the manufacturing industry by offering unprecedented design flexibility for components. This method allows engineers and designers to create complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. The versatility of injection molded plastic components enables them to be tailored for specific applications, accommodating intricate designs without compromising structural integrity.

Plastic injection molding has revolutionized the manufacturing industry by offering unprecedented design flexibility for components. This method allows engineers and designers to create complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. The versatility of injection molded plastic components enables them to be tailored for specific applications, accommodating intricate designs without compromising structural integrity.

Moreover, the capacity for rapid prototyping enhances the design process further. Designers can quickly iterate on their models, making adjustments and improvements in response to performance testing or aesthetic needs. This agility not only speeds up the development cycle but also facilitates more innovative and functional product designs. The result is a more efficient manufacturing process that meets the ever-evolving demands of the market while maintaining the high standards of quality and performance.

Achieving Consistent Quality and Precision in Manufacturing Processes

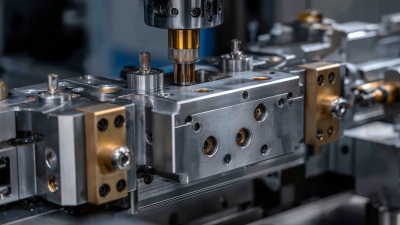

Plastic injection molding is a crucial process in modern manufacturing, offering unparalleled consistency and precision in producing parts. This method allows manufacturers to create complex shapes and intricate designs with tight tolerances, ensuring that each injection-molded part meets specific dimensions and functionality requirements. The ability to repeat this process reliably leads to a higher standard of quality, reducing the likelihood of defects and the need for costly rework.

Moreover, plastic injection molding facilitates rapid production cycles, which means that high volumes of parts can be produced quickly without sacrificing quality. This efficiency is vital in industries where time-to-market is critical. Advanced technologies and methodologies, such as computer-aided design (CAD) and simulation tools, further enhance the precision of the injection molding process, enabling manufacturers to optimize their designs and predict potential issues before production begins. As a result, manufacturers can deliver consistent quality while remaining competitive in the ever-evolving market landscape.

10 Key Advantages of Using Plastic Injection Molded Parts

The Environmental Benefits of Choosing Plastic Injection Molded Parts

Plastic injection molded parts offer significant environmental benefits that set them apart from traditional manufacturing methods. One of the primary advantages is the efficient use of materials. The injection molding process minimizes waste, as it allows for precise control over the amount of plastic used, reducing excess scrap compared to other methods. Additionally, many injection molded products can incorporate recycled plastics, further decreasing the carbon footprint and promoting sustainability within the manufacturing sector.

Plastic injection molded parts offer significant environmental benefits that set them apart from traditional manufacturing methods. One of the primary advantages is the efficient use of materials. The injection molding process minimizes waste, as it allows for precise control over the amount of plastic used, reducing excess scrap compared to other methods. Additionally, many injection molded products can incorporate recycled plastics, further decreasing the carbon footprint and promoting sustainability within the manufacturing sector.

Moreover, the energy efficiency of plastic injection molding contributes to its environmental appeal. Modern injection molding machines are designed to consume less energy while maintaining high productivity levels. This reduction in energy consumption not only lowers operation costs but also diminishes greenhouse gas emissions associated with energy production. Furthermore, the durability of plastic injection molded parts means they often require fewer resources for maintenance or replacement over time, leading to a longer lifecycle that benefits both manufacturers and consumers. This commitment to sustainability through recycling, reduced waste, and energy efficiency underlines the growing importance of plastic injection molded parts in environmentally responsible manufacturing practices.

Related Posts

-

How to Successfully Optimize Your Plastic Injection Molding Process for Maximum Efficiency

-

How to Choose the Right Injection Molding Tooling for Your Production Needs

-

How to Optimize Your Plastic Injection Tooling Process for Maximum Efficiency

-

How to Optimize Your Production Process with Medical Injection Moulding Techniques

-

Quality Driven Global Success of Prototype Injection Molding from China

-

7 Unmatched Strategies for Optimizing Your Injection Tooling Process