5 Key Benefits of Investing in Injection Tooling for Global Buyers

In today's rapidly evolving manufacturing landscape, global buyers are increasingly recognizing the strategic advantages of investing in injection tooling. According to a recent report by the Markets and Markets Research, the global injection molding market is projected to reach USD 345.51 billion by 2027, growing at a CAGR of 5.5% from 2020 to 2027. This shift underscores the critical role of injection tooling in enhancing production efficiency, cost-effectiveness, and product versatility. By leveraging advanced injection tooling technologies, companies can significantly reduce material waste and production time, while also improving the quality of their end products. In this blog, we will explore five key benefits of investing in injection tooling that can empower global buyers to stay competitive and meet the growing demands of various industries.

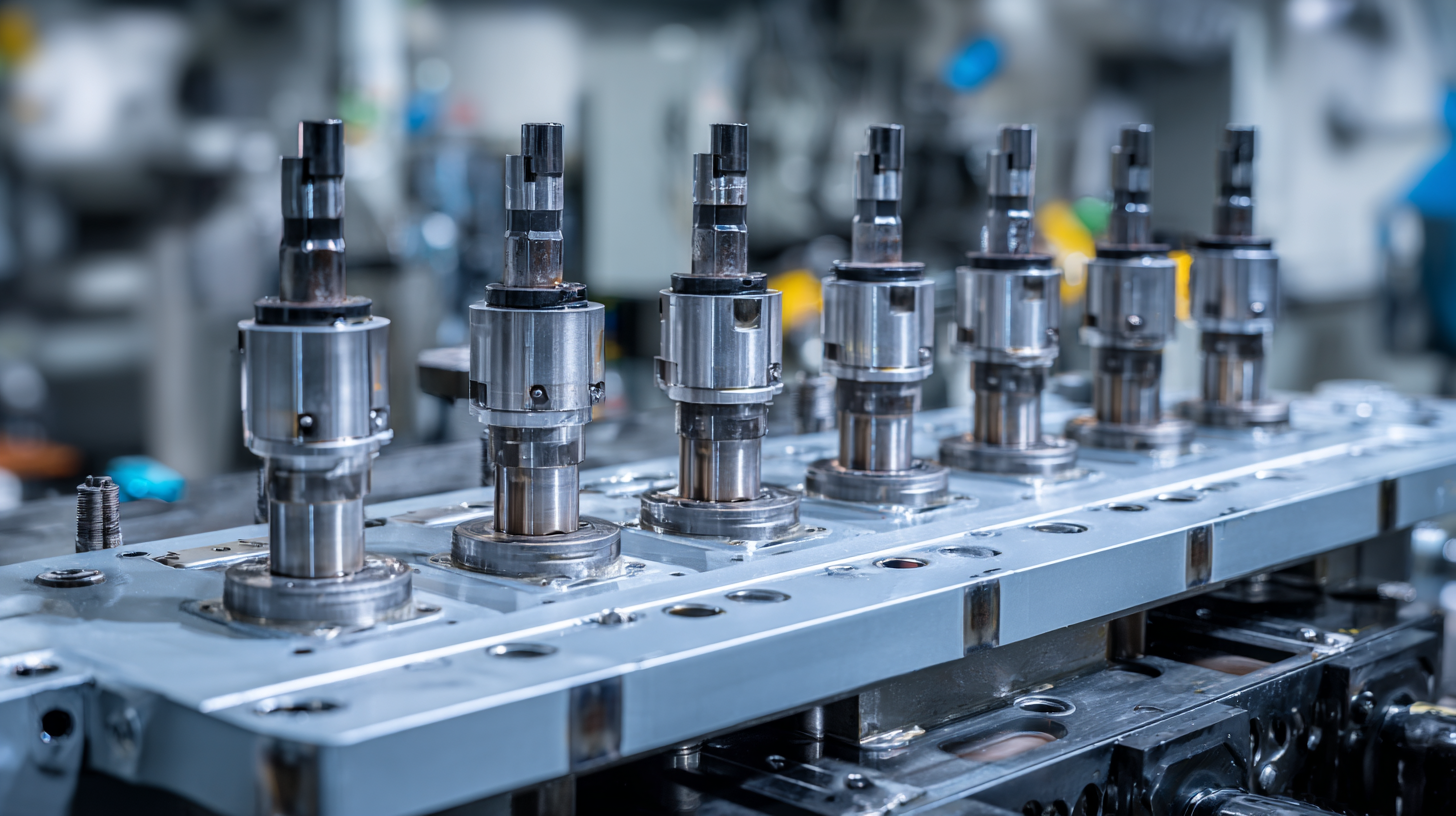

Understanding Injection Tooling: A Global Perspective

Injection tooling, a pivotal manufacturing process in various industries, plays a significant role in facilitating global trade. Understanding its nuances allows buyers to leverage its full potential. According to a report by Statista, the global injection molding market size was valued at approximately $96.5 billion in 2021, with projections suggesting it will exceed $133 billion by 2028. This growth reflects the increasing demand for precision-engineered components across sectors such as automotive, consumer goods, and healthcare.

Moreover, the shift towards sustainability is accelerating the adoption of advanced injection tooling technologies. The Plastics Industry Association estimates that enhancing tooling efficiency can reduce waste by up to 30%, fundamentally transforming production lines into greener operations. By incorporating innovative designs and materials, global buyers can not only improve product quality but also meet the rising consumer demand for environmentally friendly alternatives. As competition intensifies globally, understanding the intricacies of injection tooling can significantly enhance a buyer's strategic position in the market.

Cost Efficiency: Maximizing Your Investment in Tooling Solutions

Investing in injection tooling remains crucial for global buyers, especially when considering cost efficiency. By optimizing your investment in tooling solutions, you can significantly reduce operational costs while enhancing production capabilities. Advanced tooling materials play a vital role in this aspect, offering improved durability and performance. For instance, incorporating ceramic end mills and coated materials like polycrystalline diamond and cubic boron nitride can extend tool life and reduce maintenance costs, ultimately leading to a higher return on investment.

Upskilling your workforce is another critical strategy. Equipping aerospace machinists with cutting-edge knowledge about the latest tooling technologies can drive efficiency and innovation. By exposing teams to advancements in machining techniques and strategies for leveraging these tools, companies can better position themselves in a competitive market. Emphasizing continuous training ensures that your workforce remains adept at utilizing the best tooling solutions available, thus maximizing your investment potential.

Moreover, organizations should focus on managing operational costs effectively while driving growth. Implementing strategies that reinforce cost efficiency, such as bulk purchasing of tooling solutions and fostering supplier relationships, can convert potential challenges into opportunities for sustainable development. By prioritizing these practices, global buyers can secure a robust foundation for their manufacturing processes, ensuring long-term success.

5 Key Benefits of Investing in Injection Tooling for Global Buyers

Quality Assurance: Consistency in Production with Injection Tooling

Quality assurance plays a crucial role in maintaining consistency in production within the injection tooling process. As products undergo extensive fabrication, various factors can impact their quality, making it essential to implement robust systems that can adapt to these challenges. One innovative solution is the development of an adaptive adjustment system designed to enhance quality control by utilizing intelligent temperature compensation. By ensuring temperature stability throughout the injection molding process, manufacturers can significantly reduce variability, leading to a more uniform product output.

Moreover, addressing the common pitfalls in injection molding is equally vital for upholding production efficiency. Identifying the top mistakes that often lead to inefficiencies and scrap can pave the way for effective solutions. Incorporating advanced monitoring techniques, such as in-situ measurement of polymer melt flow at the injection mold gate, can help mitigate issues stemming from transient changes in flow rates. These proactive measures not only improve product reliability but also enhance overall production processes, affirming the importance of quality assurance in achieving optimal results in injection molding operations.

Customization Options: Tailoring Solutions for Diverse Needs

In today's rapidly evolving market, customization is paramount for businesses seeking to maintain a competitive edge. Investing in injection tooling allows global buyers to tailor solutions that meet diverse needs, making it an attractive option for various industries. Customization in tooling not only enhances product performance and quality but also enables manufacturers to respond swiftly to changing consumer demands. This adaptability helps businesses efficiently allocate resources and minimize waste, ultimately leading to greater profitability.

Moreover, as industries increasingly incorporate advanced technologies, the need for unique tooling solutions becomes even more critical. Just as AI is reshaping various sectors by providing personalized and adaptive experiences, injection tooling can be designed with specific functionalities that cater to individual business requirements. This tailored approach ensures that companies can optimize their production processes while also exploring innovative avenues for growth. By leveraging custom injection tooling, businesses position themselves to thrive amid dynamic market conditions, ensuring their offerings remain relevant and in demand.

5 Key Benefits of Investing in Injection Tooling for Global Buyers - Customization Options: Tailoring Solutions for Diverse Needs

| Benefit | Description | Customization Options | Application Areas |

|---|---|---|---|

| Cost Efficiency | Reduces production costs through mass production. | Scalable designs for various volumes. | Automotive, Consumer Electronics |

| Rapid Prototyping | Quickly tests designs before full scale production. | Short-run molds for testing. | Medical Devices, Toys |

| High Precision | Ensures consistent product quality and dimensions. | Tailored molds for intricate designs. | Aerospace, Industrial Equipment |

| Material Variety | Utilizes a wide range of materials for production. | Custom material blends for specific applications. | Packaging, Consumer Goods |

| Sustainability | Incorporates practices that reduce waste and energy use. | Eco-friendly material options available. | Renewable Products, Green Technologies |

Sustainability Advantages: Eco-Friendly Practices in Injection Tooling

In recent years, sustainability has emerged as a pivotal concern for industries worldwide, and injection tooling is no exception. By investing in eco-friendly practices within injection tooling, global buyers can significantly reduce their environmental footprint. Modern injection molding processes utilize recyclable materials and energy-efficient machinery, which minimize waste and lower energy consumption. This not only benefits the planet but also enhances a company's brand image as consumers increasingly favor environmentally responsible products.

Moreover, advancements in injection tooling technology have made it easier to implement sustainable practices. For instance, automated systems now optimize material usage, reducing scrap rates and enabling manufacturers to maintain high quality while being conscious of their resource consumption. Additionally, companies can explore biodegradable polymers, which offer the functionality needed for various applications without the long-term environmental impact of traditional plastics. Embracing these innovations not only helps in meeting regulatory demands but also positions businesses as leaders in sustainable manufacturing.