Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

Injection mold fabrication is a crucial process in the manufacturing sector, accounting for nearly 30% of the plastic parts produced annually. As industries strive for efficiency and precision, alternatives to traditional injection molding methods are gaining traction. According to a report by MarketsandMarkets, the global injection molding market is projected to reach USD 300 billion by 2025, underscoring the increasing reliance on advanced techniques. With the rise of materials like thermoplastics and bioplastics, beginners in the field must understand not only the process of injection mold fabrication but also the various alternatives that can optimize production. This guide aims to equip novices with essential knowledge and insights into both traditional and emerging alternatives, paving the way for innovative solutions in their manufacturing journey.

Understanding the Basics of Injection Molding: Key Concepts and Terminology

Injection molding is a crucial manufacturing process widely used in various industries for producing plastic parts. At its core, the process involves injecting molten plastic into a mold, where it cools and solidifies to form a specific shape. One of the key concepts in injection molding is the "shot size", which refers to the volume of material injected into the mold. According to a report by the American Injection Molding Institute, optimizing shot size is essential for minimizing waste and maximizing efficiency, as even minor adjustments can significantly affect production costs.

Understanding the terminology associated with injection molding is equally important. Terms such as "clamping force" and "cycle time" play a vital role in the overall efficiency of the process. Clamping force is the strength needed to keep the mold closed during injection, and it's critical to ensure quality parts without defects. The cycle time, which is the duration from the start of injection to the completion of the part ejection, typically ranges from 15 to 30 seconds for most applications, as highlighted in the 2022 report by Plastics Technology. Mastering these fundamental concepts is essential for beginners looking to gain insights into the intricacies of injection mold fabrication.

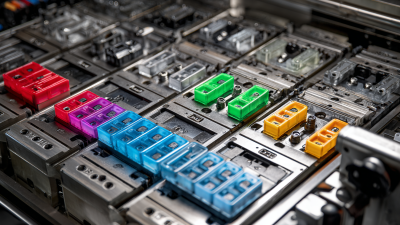

Essential Tools and Materials for Successful Injection Mold Fabrication

When embarking on the journey of injection mold fabrication, having the right tools and materials is essential for achieving success. Key tools include a precision milling machine, which is vital for creating the detailed profiles required for molds. Additionally, CNC machines can enhance accuracy and efficiency, allowing for complex shapes and uniformity in production. Incorporating quality control instruments, such as calipers and gauges, will ensure every component meets the precise specifications needed for effective mold operation.

In terms of materials, selecting the right type of thermoplastic is crucial. Common choices include ABS, nylon, and polypropylene, each offering unique properties suited for different applications. It’s also important to have a reliable release agent to facilitate easy mold removal and extend the lifespan of your molds.

**Tip:** Don’t underestimate the importance of thorough research on the materials you choose; understanding their thermal properties can greatly influence your molding process. Additionally, consider investing in ergonomic hand tools such as spatulas and scrapers, which can contribute to a safer and more efficient workspace. Remember, preparation is key in minimizing errors and optimizing your workflow.

Step-by-Step Process of Designing Your First Injection Mold

Designing your first injection mold can seem daunting, but it can be broken down into manageable steps. The initial stage involves conceptualizing your design, where CAD software plays a crucial role. This technology allows beginners to visualize their products and make necessary adjustments before moving forward. Understanding the interaction between the mold and the finished parts is essential, particularly when it comes to complex internal cavities or organic shapes that might benefit from advanced manufacturing techniques.

As you develop your design further, consider how modern advancements, such as 3D printing, can complement traditional injection molding. These technologies enable the creation of prototypes and even final products without the lengthy process of fabricating molds. Embracing a digital-first approach can lead to reduced lead times, fewer components, and enhanced design flexibility. Companies are effectively leveraging CNC machining and advanced materials to optimize their production capabilities while maintaining high-quality standards in their molds. By following these steps, beginners can tremendously enhance their skills and confidence in injection mold fabrication.

Injection Mold Fabrication Process Steps

Best Practices for Troubleshooting Common Injection Molding Issues

Injection molding is a complex process that can present various challenges, particularly for beginners. According to the "2019 Injection Molding Survey" published by Plastics Technology, nearly 40% of manufacturers reported issues with defective parts due to improper mold setup and maintenance. To troubleshoot these common issues effectively, it’s crucial to develop a systematic approach.

Injection molding is a complex process that can present various challenges, particularly for beginners. According to the "2019 Injection Molding Survey" published by Plastics Technology, nearly 40% of manufacturers reported issues with defective parts due to improper mold setup and maintenance. To troubleshoot these common issues effectively, it’s crucial to develop a systematic approach.

One of the primary problems encountered is poor part quality, often manifested as warping or dimensional inaccuracies. The American Society for Testing and Materials (ASTM) emphasizes the importance of proper temperature control, advocating that maintaining an optimal melt temperature—between 180°C and 220°C—is essential for achieving uniform part dimensions and reducing the risk of defects. Additionally, consistent pressure during injection, supported by proper machine calibration, can significantly mitigate defects related to material flow.

Furthermore, understanding the role of drying procedures cannot be overstated. The "Technologies in Injection Molding" report by the Society of Plastics Engineers reveals that up to 60% of manufacturers overlook proper resin drying, which can lead to moisture-related defects affecting mechanical properties. Implementing best practices such as pre-drying resins based on specific material guidelines is crucial for improving overall product quality and minimizing production costs. By focusing on these areas and staying informed about industry standards, beginners can better navigate the complexities of injection molding.

Advanced Techniques and Tips for Optimizing Mold Performance

In the realm of injection mold fabrication, the use of advanced techniques such as conformal cooling channels (CCCs) is crucial for optimizing mold performance. CCCs are designed to enhance the cooling rate of the molded parts, ensuring uniform temperature distribution due to their proximity to the mold surface. By implementing CCCs, manufacturers can significantly reduce cycle times and improve part quality by minimizing warpage and surface defects.

When embarking on your injection mold design journey, consider incorporating flexible dosing solutions like hollow microneedles. These innovative tools allow for precise control over the dosage of substances, making them particularly effective for applications like transdermal drug delivery. Their adaptability to various drug formulations opens up new avenues for medical applications while streamlining the manufacturing process.

Tips for Success:

- Always conduct thorough simulations of the cooling process to ensure optimal channel placement in your mold design.

- Experiment with different materials for your hollow microneedles to find the best match for your specific dosage requirements.

- Regularly assess and fine-tune your mold parameters based on trial runs to achieve peak performance.

Related Posts

-

Understanding Characteristics and Applications of Best Injection Molding Tooling Variants

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry

-

Quality Driven Global Success of Prototype Injection Molding from China

-

5 Key Benefits of Investing in Injection Tooling for Global Buyers

-

Creative Examples of Successful Injection Molding Applications Across Industries