How to Successfully Optimize Your Plastic Injection Molding Process for Maximum Efficiency

In the highly competitive landscape of manufacturing, optimizing the plastic injection molding process is crucial for achieving maximum efficiency and cost-effectiveness. According to a report by Grand View Research, the global plastic injection molding market is expected to reach USD 382.5 billion by 2025, highlighting the demand for innovative production techniques that can enhance output and minimize waste. Furthermore, studies indicate that efficient injection molding processes can reduce cycle times by up to 50%, thereby significantly increasing productivity. As industries face pressure to accelerate production while maintaining quality, adopting best practices in plastic injection molding becomes not just beneficial but essential for sustained growth and profitability. This guide will provide actionable insights and strategies for successfully optimizing your plastic injection molding operations, ensuring your business remains competitive in an evolving market.

Identifying Key Parameters for Plastic Injection Molding Process Optimization

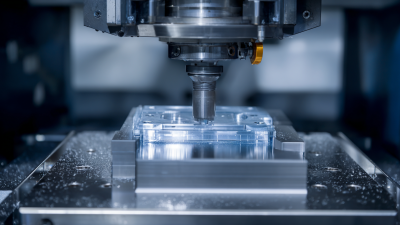

To successfully optimize the plastic injection molding process, it is essential to identify and finely tune key parameters. One of the primary factors is temperature control. The melting temperature of the plastic must be meticulously monitored to ensure it flows correctly into the mold. Too high a temperature can lead to material degradation, while too low can result in incomplete filling, both affecting the quality of the final product.

Another critical parameter is injection speed. This influences how quickly the molten plastic is introduced into the mold cavity. Adjusting injection speed can help reduce cycle times, minimize defects like sink marks, and improve the overall dimensional consistency of the parts produced. Additionally, optimizing cooling time is crucial. Effective cooling not only solidifies the part but also reduces the cycle time, contributing to greater productivity. By focusing on these key parameters—temperature, injection speed, and cooling time—manufacturers can achieve significant improvements in both efficiency and output quality in the plastic injection molding process.

Plastic Injection Molding Process Optimization

This chart illustrates key parameters that impact the efficiency of the plastic injection molding process. By optimizing each parameter, manufacturers can significantly enhance their production efficiency.

Implementing Advanced Simulation Techniques for Enhanced Efficiency

Implementing advanced simulation techniques plays a pivotal role in enhancing the efficiency of the plastic injection molding process. By utilizing simulation software, manufacturers can create precise models of their molding processes before production begins. This allows for thorough analysis of various parameters, including temperature, pressure, and flow rates. With these insights, potential issues such as air traps, uneven cooling, or material degradation can be identified and rectified early, ultimately reducing waste and cycle times.

Moreover, simulation techniques enable the optimization of mold designs and material selection. By experimenting with different configurations and materials in a virtual environment, engineers can determine the most effective combinations to produce high-quality parts at reduced costs. Advanced simulations take into account real-world variables, leading to more reliable predictions of product performance and manufacturability. As a result, companies can streamline their operations, minimize downtime, and significantly enhance overall productivity in their injection molding processes.

Streamlining Tooling and Equipment for Improved Injection Molding Performance

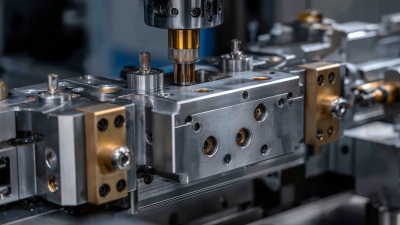

Optimizing the tooling and equipment used in plastic injection molding is crucial for enhancing overall performance and efficiency. One effective way to streamline this process is through regular maintenance and calibration of machines. Ensuring that your injection molding machines are functioning at optimal levels can prevent downtime and contribute to consistent product quality.

Optimizing the tooling and equipment used in plastic injection molding is crucial for enhancing overall performance and efficiency. One effective way to streamline this process is through regular maintenance and calibration of machines. Ensuring that your injection molding machines are functioning at optimal levels can prevent downtime and contribute to consistent product quality.

Tips: Schedule routine inspections and maintenance to identify any wear and tear on molds and machinery. This proactive approach minimizes unexpected failures and allows for smooth operations.

Another key aspect is to invest in advanced tooling solutions that cater to specific project requirements. Using high-quality, precision-engineered molds can significantly reduce cycle times and improve the overall finish of the final product. Additionally, consider using quick-change molds to facilitate faster transitions between different production runs.

Tips: Evaluate your current tooling designs and identify opportunities for upgrades. Look for molds that are easier to handle and set up, allowing for a more efficient production environment.

Training and Involving Staff in Continuous Improvement Initiatives

Training and involving staff in continuous improvement initiatives is crucial for optimizing the plastic injection molding process. To achieve maximum efficiency, organizations must foster a culture of learning and innovation among their workforce. This can be accomplished through regular training sessions focused on best practices in injection molding, maintenance protocols, and troubleshooting techniques. By equipping employees with the right skills and knowledge, companies can ensure that every team member contributes to the optimization process, identifying bottlenecks and proposing solutions based on their firsthand experience.

Moreover, involving staff in continuous improvement initiatives empowers them to take ownership of their tasks and encourages collaboration. Establishing feedback loops where employees can share their insights and suggestions not only enhances morale but also drives innovative thinking. Regular workshops and brainstorming sessions can facilitate discussions on potential process enhancements, with employees from different departments collaborating to implement ideas. This collaborative approach not only leads to practical improvements but also reinforces the importance of each individual’s contribution to the overall success of the injection molding operation.

Measuring and Analyzing Production Data to Drive Decision-Making

To optimize the plastic injection molding process effectively, measuring and analyzing production data is crucial. This data encompasses various metrics, including cycle times, defect rates, and material usage, all of which can provide insights into the efficiency of production. Utilizing advanced analytics tools can help manufacturers identify trends and anomalies, allowing for informed decision-making that enhances overall productivity.

By continuously monitoring key performance indicators (KPIs), companies can pinpoint inefficiencies in their processes. For instance, analyzing cycle time data may reveal bottlenecks that slow down production. Similarly, defect rate statistics can guide quality control measures, informing adjustments in machine parameters or tooling. With real-time data acquisition systems, manufacturers can make proactive adjustments, reducing downtime and waste, ultimately leading to improved output and cost savings.

Related Posts

-

Common Challenges Faced in Mold Plastic Injection Processes

-

How to Optimize Your Plastic Injection Tooling Process for Maximum Efficiency

-

7 Reasons Why Short Run Injection Molding is the Best Choice for Your Business

-

Exploring Innovative Alternatives to Injection Moldable Plastics for Sustainable Production

-

7 Unmatched Strategies for Optimizing Your Injection Tooling Process

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry