How to Optimize Your Plastic Injection Tooling Process for Maximum Efficiency

Optimizing your plastic injection tooling process is crucial for manufacturers aiming to maximize efficiency and reduce production costs. In a competitive market, ensuring that your tooling is not only efficient but also maintains high-quality standards can make a significant difference in overall productivity.

Optimizing your plastic injection tooling process is crucial for manufacturers aiming to maximize efficiency and reduce production costs. In a competitive market, ensuring that your tooling is not only efficient but also maintains high-quality standards can make a significant difference in overall productivity.

This blog will explore various strategies to enhance your plastic injection tooling processes, from selecting the right materials and designs to implementing advanced technologies and maintenance practices.

By understanding the key elements and best practices for optimization, manufacturers can streamline their operations, minimize downtime, and ultimately achieve a more efficient production cycle.

Join us as we delve into practical tips and insights that can transform your approach to plastic injection tooling and drive your business towards greater success.

Understanding the Fundamentals of Plastic Injection Tooling

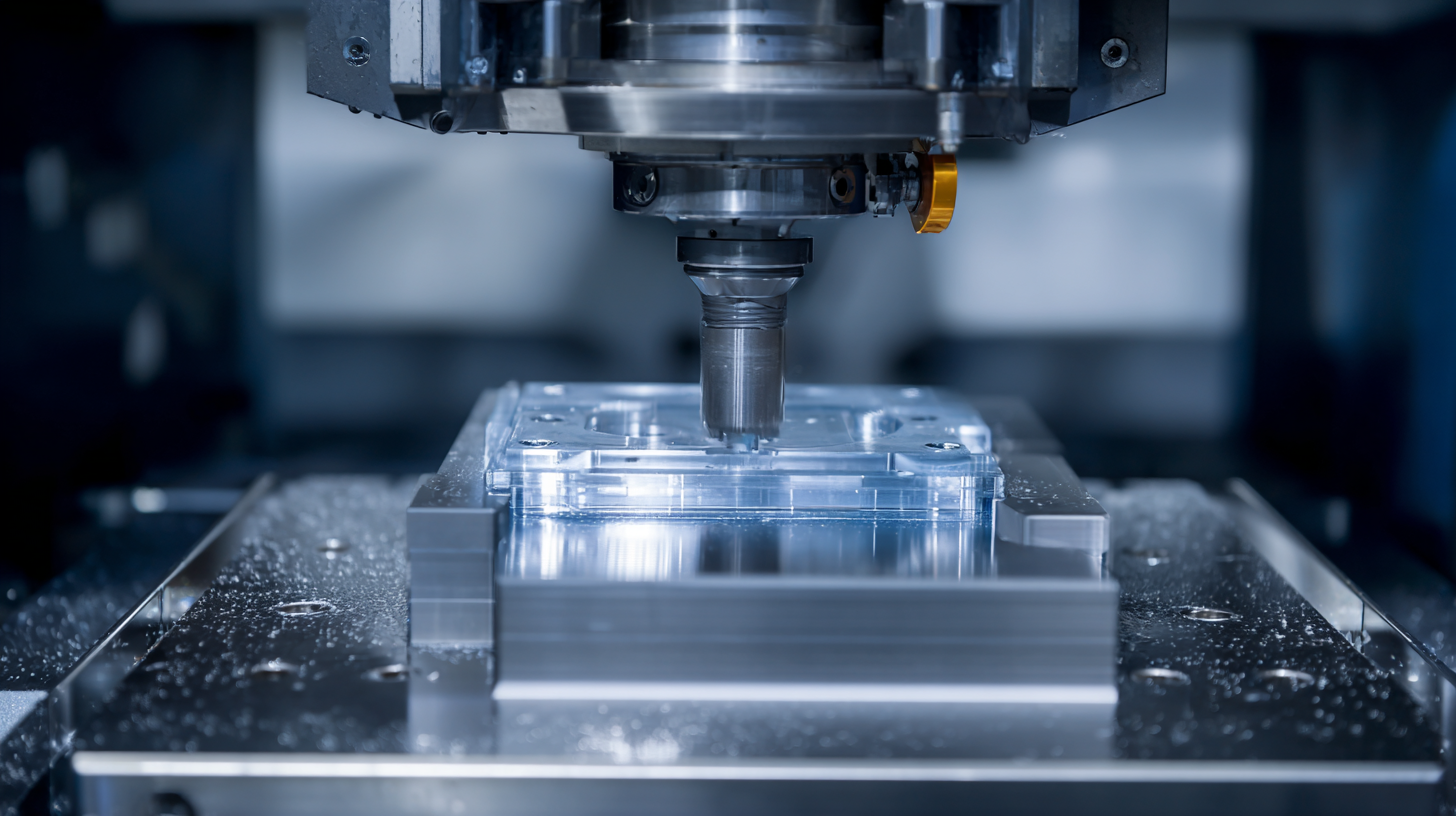

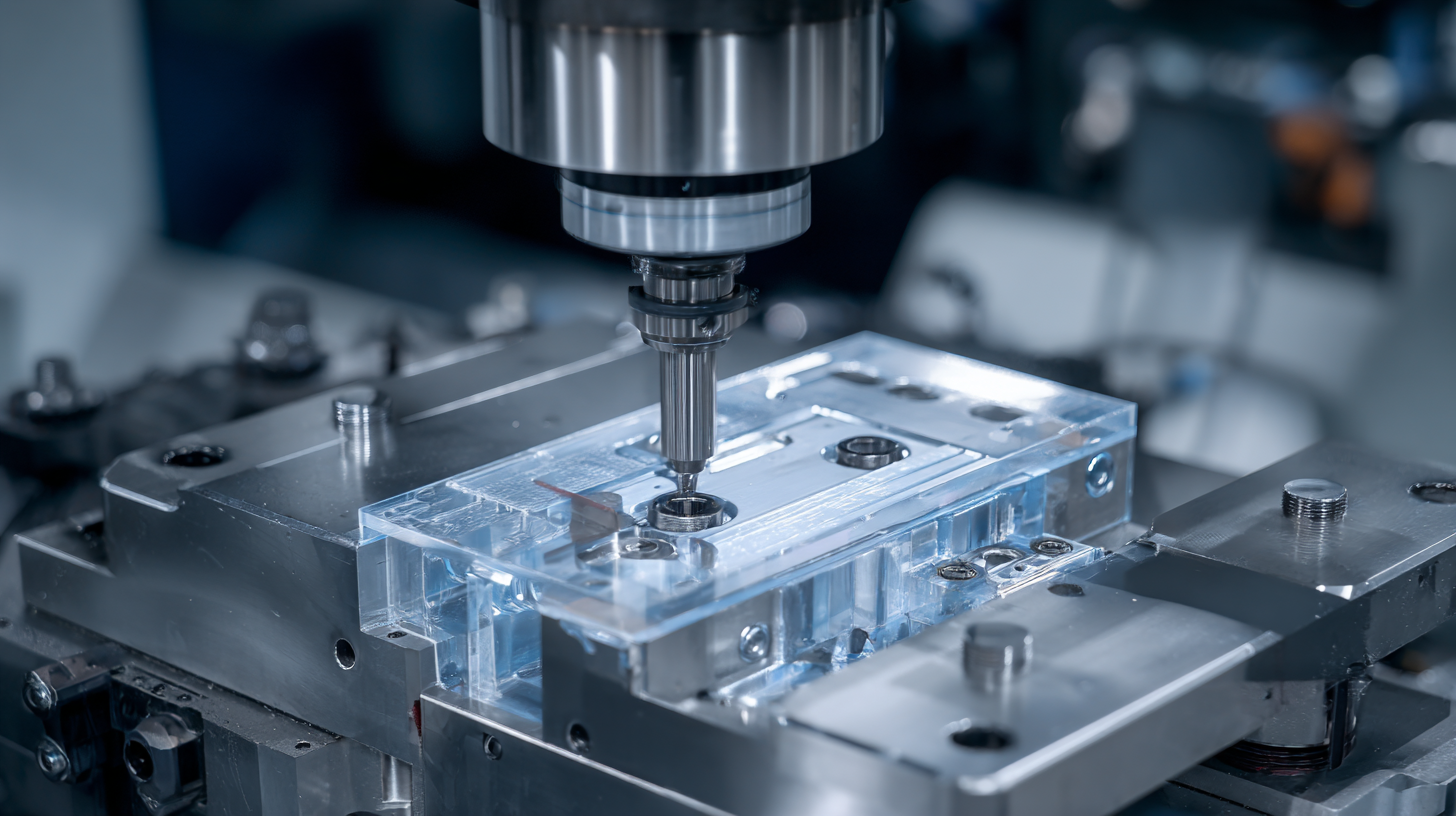

Plastic injection tooling is a critical component in the manufacturing process, significantly influencing production speed and cost-efficiency. Understanding the fundamentals of plastic injection tooling involves grasping the design, materials, and processes that enhance tooling performance. According to a study by the Society of Plastics Engineers (SPE), optimizing tooling processes can improve production efficiency by up to 30%, thereby reducing costs and lead times significantly.

One key factor in maximizing efficiency is the selection of suitable materials for the molds. High-quality steel and aluminum have different thermal properties, which can affect cycle times and durability. The SPE research indicates that injection molds made from high-grade steel can last up to five times longer than their aluminum counterparts, making them a more cost-effective option in the long run. Furthermore, incorporating advanced mold cooling techniques can reduce cycle times by as much as 25%, further enhancing the overall efficiency of the injection process.

Moreover, leveraging data-driven analytics during the tooling design phase can lead to significant improvements. Implementing simulation software to predict potential issues before production begins can save manufacturers an average of 20% in tooling costs and minimize downtime. As reported by the American Society for Quality (ASQ), manufacturers utilizing these technologies are not only seeing faster turnaround times but also improved product quality, demonstrating how a deeper understanding of plastic injection tooling fundamentals can lead to substantial operational benefits.

Identifying Key Variables that Impact Tooling Efficiency

To optimize your plastic injection tooling process, it is crucial to identify and understand the key variables that impact tooling efficiency. The first variable to consider is the choice of materials. The type and quality of materials used in the tooling can significantly affect the lifespan and performance of the tools. Using high-grade steel or specialized alloys can reduce wear and tear, resulting in fewer changes and downtime.

Another critical factor is the precision of the machining process. Ensuring that machined components are manufactured to the exact specifications reduces the likelihood of defects during production. Regular maintenance of machinery also plays a vital role. Keeping machinery well-maintained minimizes unexpected breakdowns and prolongs the life of the tooling.

Tip: Implement a routine inspection schedule for your tooling to identify wear patterns early and address issues before they escalate. Additionally, consider utilizing simulation software to predict potential failures and optimize the tooling design based on real-time data. This proactive approach can save time and resources while enhancing overall efficiency.

Implementing Advanced Technology for Process Optimization

Implementing advanced technologies in the plastic injection tooling process can drastically enhance efficiency and accuracy. According to a report by MarketsandMarkets, the global injection molding machine market is expected to grow from $18.55 billion in 2020 to $23.74 billion by 2025, indicating a significant trend towards technological adoption in manufacturing. By integrating real-time data analytics, manufacturers can identify bottlenecks in the tooling process and adjust parameters dynamically, thereby reducing cycle times and minimizing waste.

Furthermore, utilizing technologies such as Internet of Things (IoT) sensors can offer unprecedented insights into machinery performance. A study from the American Society of Plastics Engineers indicates that IoT implementation can lead to up to a 15% reduction in operational costs. By monitoring tooling temperatures and pressure in real-time, companies can optimize their setups, leading to improved product quality and consistency. The evolution of advanced robotics also plays a crucial role; automated processes can reduce human error, enhancing throughput and maintaining high production standards.

Together, these technologies pave the way for an optimized, highly efficient plastic injection tooling process.

Establishing a Robust Maintenance Schedule for Tools

Establishing a robust maintenance schedule for tools is crucial to optimizing your plastic injection tooling process. Regular maintenance ensures that machinery operates at peak efficiency, reducing downtime caused by unexpected breakdowns. A well-structured maintenance plan involves not only routine inspections but also detailed records of tool performance and past repairs. By analyzing these records, manufacturers can identify patterns that might lead to future issues, allowing for proactive adjustments.

Incorporating predictive maintenance techniques can significantly enhance the effectiveness of your schedule. Utilizing technology such as sensors and monitoring systems helps in detecting wear and tear before it becomes critical. This real-time data allows for timely interventions and extends the life of your tooling equipment. Moreover, training staff on the importance of maintenance and how to recognize signs of tool degradation can empower them to take an active role in the process. Such collective efforts create a culture prioritizing efficiency and can lead to significant improvements in production output.

Tool Maintenance Schedule Impact on Efficiency

This chart illustrates the correlation between the frequency of maintenance checks and the operational efficiency of injection molding tools. Regular maintenance can significantly enhance productivity.

Continuous Improvement: Analyzing Data for Ongoing Enhancements

To achieve maximum efficiency in plastic injection tooling, continuous improvement through data analysis is paramount. The integration of data-driven methodologies can significantly streamline operations. For instance, according to a report from the Plastics Industry Association, manufacturers that implement data analytics in their production processes have seen productivity increases of up to 20%. By monitoring key performance indicators (KPIs) such as cycle time, defect rates, and material utilization, companies can identify bottlenecks and areas ripe for enhancement.

Moreover, utilizing predictive analytics enables companies to preemptively address potential issues before they escalate. A study by the American Society for Quality reveals that organizations that leverage predictive maintenance strategies can reduce downtime by approximately 30%. By analyzing historical data on machine performance, manufacturers can discern patterns and make informed decisions that lead to more efficient tooling processes. This proactive approach not only enhances production efficiency but also fosters a culture of continuous improvement within the organization, ultimately driving greater competitiveness in the market.

How to Optimize Your Plastic Injection Tooling Process for Maximum Efficiency

| Tooling Parameter | Optimal Value | Current Value | Improvement (%) | Notes |

|---|---|---|---|---|

| Cycle Time | 30 seconds | 40 seconds | 25% | Reduce cooling time |

| Material Waste | 5% | 10% | 50% | Optimize scrap rate |

| Defect Rate | 2% | 5% | 60% | Improve quality checks |

| Energy Consumption | 50 kWh | 70 kWh | 28.57% | Implement energy audits |

| Setup Time | 15 minutes | 25 minutes | 40% | Streamline procedures |

Related Posts

-

Exploring Innovative Alternatives to Mold Plastic Injection in Modern Manufacturing: Trends and Insights

-

Common Challenges Faced in Mold Plastic Injection Processes

-

Exploring Innovative Alternatives to Injection Moldable Plastics for Sustainable Production

-

How to Choose the Right Injection Molding Tooling for Your Production Needs

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry

-

5 Key Benefits of Investing in Injection Tooling for Global Buyers