How to Optimize Your Production Process with Medical Injection Moulding Techniques

In the ever-evolving landscape of medical manufacturing, optimizing production processes has become paramount for ensuring efficiency and quality. One of the most effective methods to achieve this is through the implementation of medical injection moulding techniques. This advanced manufacturing process allows for precise and consistent production of complex medical components, catering to the stringent requirements of the healthcare industry. In this guide, we will explore various strategies to enhance your production workflow utilizing medical injection moulding. By understanding the key principles and best practices, manufacturers can reduce waste, improve turnaround times, and ultimately enhance product reliability. Join us as we delve into actionable insights that will empower you to harness the full potential of medical injection moulding in your production environment.

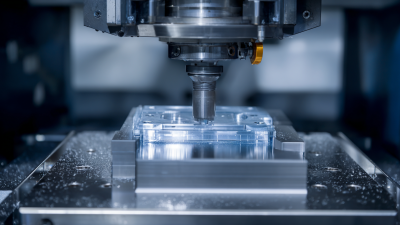

Understanding the Basics of Medical Injection Moulding and Its Applications in Production Efficiency

Medical injection moulding is crucial for enhancing production efficiency, especially in sectors like biomedical applications where precision and reliability are paramount. With the global injection molding market projected to reach USD 38.01 billion by 2033, growing at a CAGR of 5.94%, it’s clear that businesses are increasingly leveraging these techniques. Effective design and analysis of injection molds play a vital role in producing high-quality plastic components that meet stringent medical standards. By employing methods such as the Taguchi approach and Analysis of Variance (ANOVA), manufacturers can optimize parameters to reduce defects like weight and warpage in PET preforms.

Tips: To elevate production efficiency, consider integrating conformal cooling designs into your injection moulding process. This methodology not only enhances cooling performance but also significantly reduces cycle times, leading to higher output. Furthermore, adopting advanced temperature control technologies ensures consistent product quality, which is essential in maintaining compliance with healthcare regulations. With such innovations, manufacturers can navigate the complexities of the medical sector, positioning themselves ahead in a competitive marketplace.

Key Benefits of Medical Injection Moulding Techniques in Optimizing Production Workflows and Costs

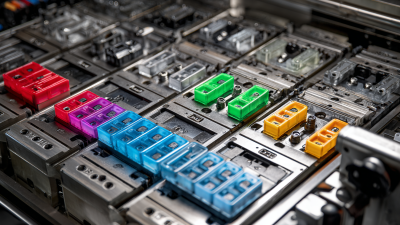

Medical injection moulding techniques offer a range of key benefits that can significantly optimize production workflows and reduce costs in the manufacturing sector. One of the primary advantages is the ability to produce intricate and precise components that meet stringent regulatory requirements. This precision not only enhances the quality of medical devices but also minimizes waste, thereby lowering material costs.

By employing advanced moulding techniques, manufacturers can achieve higher production rates, ensuring that they meet market demands efficiently.

Additionally, the scalability of medical injection moulding allows for flexible production adjustments based on changing needs. This adaptability facilitates quicker turnaround times for new product designs or modifications, enabling companies to respond to market trends without incurring excessive costs.

Furthermore, the integration of automation in the injection moulding process can lead to enhanced consistency and reliability, streamlining workflows and further driving down production costs. As a result, businesses that leverage these techniques can improve their overall operational efficiency while maintaining high standards of quality and compliance.

Industry Standards and Compliance: Ensuring Quality in Medical Injection Moulding Processes

In the realm of medical injection moulding, maintaining rigorous industry standards and compliance is critical to ensuring product safety and efficacy. According to a report by the Medical Device Manufacturers Association (MDMA), up to 80% of companies in the medical device sector identify compliance with regulatory standards as a significant challenge in their production processes. These standards, which include ISO 13485 and the FDA's 21 CFR Part 820, mandate comprehensive quality management systems (QMS) that not only govern material selection but also enforce stringent testing protocols throughout the manufacturing process.

Achieving compliance requires a proactive approach to quality assurance, emphasizing the importance of validated processes and comprehensive documentation. The American Society for Quality suggests that organizations implementing robust documentation practices can reduce production errors by as much as 30%. This statistic highlights the correlation between thorough documentation—encompassing everything from material traceability to environmental controls—and the overall quality of manufactured products. As the demand for medical devices grows, staying abreast of industry compliance not only enhances product reliability but also fortifies a company's competitive edge in the marketplace.

Advanced Technologies: Incorporating Automation and Precision in Medical Injection Moulding

Incorporating automation and precision into medical injection moulding is essential for optimizing production processes in the ever-evolving healthcare landscape. Advanced technologies such as laser machining are increasingly being integrated into manufacturing workflows, enabling manufacturers to produce intricate medical device components efficiently. These technologies offer enhanced precision and reduce waste, making them indispensable in the production of high-performance materials that meet stringent regulatory standards.

The integration of servo-electric drives into injection moulding machines signifies another pivotal development, as these systems enhance both speed and accuracy. By leveraging these advanced systems, manufacturers can achieve consistent quality while reducing energy consumption. The ongoing evolution in smart manufacturing, driven by digital intelligence and mechatronic systems, further enables the medical device industry to streamline operations and maximize output quality. With an optimistic market outlook, embracing these advanced production techniques will be key to staying competitive in the burgeoning medical landscape.

Optimization of Production Process with Medical Injection Moulding Techniques

Evaluating Material Selection and Sustainability in Medical Injection Moulding for Enhanced Performance

When evaluating material selection in medical injection moulding, it is crucial to consider the unique demands of the healthcare sector. The materials used must not only meet strict regulatory standards but also ensure biocompatibility, durability, and ease of sterilization. Options such as polypropylene, polycarbonate, and thermoplastic elastomers are popular due to their resistance to harsh chemicals and their ability to withstand the rigors of medical use. Additionally, incorporating innovative materials, like bio-based plastics, can enhance product performance while aligning with sustainability efforts.

Sustainability is an increasingly important factor in the production process of medical devices. Utilizing recycled materials and minimizing waste during manufacturing can significantly reduce the environmental impact. Advanced injection moulding techniques, like multi-material injection and additive manufacturing, can allow for better material efficiency and reduced scrap rates. By focusing on sustainable practices, manufacturers not only enhance their ecological footprint but also appeal to the growing market demand for eco-friendly products in the healthcare industry. Emphasizing both material selection and sustainability can lead to improved performance and a more responsible production process.

How to Optimize Your Production Process with Medical Injection Moulding Techniques - Evaluating Material Selection and Sustainability in Medical Injection Moulding for Enhanced Performance

| Material Type | Mechanical Properties | Biocompatibility | Sustainability Rating | Applications |

|---|---|---|---|---|

| Polycarbonate (PC) | High impact resistance, excellent clarity | Class I & II compliant | Moderate | Syringes, medical devices |

| Polypropylene (PP) | Good chemical resistance, low density | Class I compliant | High | Laboratory containers, pouches |

| Thermoplastic Elastomers (TPE) | Flexible, durable with rubber-like properties | Class I compliant | Moderate | Seals, gaskets, medical tubing |

| Polyethylene (PE) | Lightweight, impact-resistant | Class I compliant | High | Packaging, disposable devices |

| Acrylic (PMMA) | High transparency, scratch-resistant | Class II compliant | Moderate | Optical devices, light guides |

Related Posts

-

Exploring Innovative Alternatives to Mold Plastic Injection in Modern Manufacturing: Trends and Insights

-

How to Optimize Your Plastic Injection Tooling Process for Maximum Efficiency

-

Quality Driven Global Success of Prototype Injection Molding from China

-

How to Successfully Optimize Your Plastic Injection Molding Process for Maximum Efficiency

-

Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

-

Understanding Characteristics and Applications of Best Injection Molding Tooling Variants