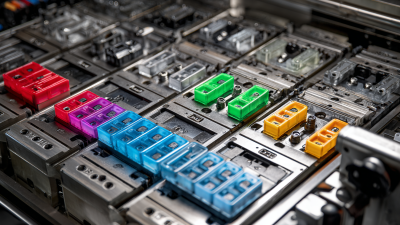

7 Reasons Why Short Run Injection Molding is the Best Choice for Your Business

In today's fast-paced manufacturing landscape, businesses are constantly seeking efficient and cost-effective solutions to meet their production needs. One option that has gained significant traction is short run injection molding, which offers a flexible approach to producing small quantities of high-quality plastic parts. According to a recent report by Grand View Research, the global injection molding market is projected to reach $372.1 billion by 2027, with a growing emphasis on short production runs to accommodate rapid prototyping and customization trends. This method not only reduces lead times but also minimizes waste, making it an environmentally friendly choice for businesses looking to streamline their operations. As companies increasingly prioritize agility and innovation, understanding the advantages of short run injection molding becomes essential for staying competitive in today's manufacturing environment.

Benefits of Short Run Injection Molding for Rapid Prototyping and Testing

Short run injection molding has emerged as an ideal solution for businesses looking to streamline their rapid prototyping and testing processes. One significant benefit is the ability to produce small quantities of parts quickly and cost-effectively. Traditional injection molding often requires large volumes to make the production viable, which can be a major drawback for companies just starting out or testing new ideas. With short run molding, businesses can create prototypes that closely resemble the final product, enabling more accurate testing and feedback without the heavy financial burden.

Furthermore, short run injection molding allows for a more flexible design approach. As development cycles shorten and market demands shift, companies can easily adjust their prototypes based on test results and consumer insights. This adaptability not only accelerates innovation but also leads to better product-market fit. By utilizing short run injection molding, businesses can ensure that their prototypes are both functional and market-ready, significantly reducing time-to-market while maintaining high standards of quality.

Cost-Effectiveness of Short Run Production in Small Batches

Short run injection molding offers a cost-effective solution for businesses looking to produce small batches of products without the hefty overhead traditionally associated with large-scale manufacturing. One of the primary advantages of this production method is the reduction in tooling costs. With shorter production runs, companies can utilize less expensive molds which are tailored specifically for their immediate needs, allowing for greater flexibility without the financial burden of a full-scale operation.

Moreover, short run production minimizes inventory costs by enabling businesses to produce items on-demand. This approach eliminates the need for warehousing large quantities of products and reduces the risks associated with overproduction. Companies can respond to market trends and customer feedback more swiftly, adjusting their production schedules to meet current demands effectively. The ability to make quick changes in design or production volume not only helps in saving costs but also enhances a company's responsiveness, ultimately leading to a more agile business strategy.

Flexibility and Customization Options for Diverse Product Needs

Short run injection molding offers exceptional flexibility and customization options, making it a compelling choice for businesses with diverse product needs. With the ability to produce small quantities, companies can quickly adapt to market demands without the financial burden of large production runs. This is especially beneficial for startups or businesses introducing new products that demand rapid iterations and adjustments based on consumer feedback.

When considering short run injection molding, it’s essential to communicate your specific requirements clearly. Providing detailed specifications, including material preferences and desired features, can help manufacturers tailor the production process to achieve the best results. Additionally, always look for a partner that offers rapid prototyping services; this can greatly enhance the development phase by allowing you to visualize and refine your product before full-scale production begins.

Another tip is to research the types of materials available for short run injection molding. Different materials can dramatically affect the final product's performance and aesthetics. By selecting the right material early in the process, you can ensure your product meets both functionality and design expectations, giving you a competitive edge in your market.

Quicker Turnaround Times to Meet Market Demands Efficiently

In today’s fast-paced market, businesses need solutions that can adapt quickly to changing demands. Short run injection molding stands out as a highly efficient option, primarily due to its significantly quicker turnaround times. According to industry data from the Society of Plastics Engineers, manufacturers utilizing short run injection molding can reduce production lead times by up to 50%, allowing them to respond to customer needs and market trends more effectively than traditional methods.

These rapid turnaround capabilities not only optimize production schedules but also enhance a company’s ability to innovate. With shorter production cycles, businesses can test new designs and products without the prolonged delays usually associated with conventional molding processes. A report by Grand View Research indicates that companies leveraging short run capabilities can bring new products to market up to 30% faster, providing a critical edge in competitive sectors. By embracing short run injection molding, businesses can fulfill market demands swiftly while minimizing overhead costs and avoiding the pitfalls of overproduction or inventory buildup.

Sustainability Advantages: Reducing Waste in Short Run Productions

In today's manufacturing landscape, businesses are increasingly focused on sustainability, and short run injection molding offers a viable solution to address waste reduction. Traditional manufacturing techniques often lead to significant material wastage due to excess production and non-optimized designs. In fact, the Thermoplastic Shredding Report indicates that approximately 30% of raw materials are wasted in conventional processes. Conversely, short run injection molding minimizes this through precise production runs that align closely with actual demand, allowing companies to produce only what is necessary.

Furthermore, the environmental impact of shortened production cycles cannot be understated. According to a study by the Society of Plastics Engineers, implementing short run injection molding can reduce carbon emissions by up to 40%. This is achieved not only by decreasing the volume of materials used but also by streamlining the manufacturing process itself. By utilizing the latest technologies, businesses can effectively recycle and repurpose materials, contributing to a circular economy. This approach not only supports business sustainability initiatives but also meets the growing consumer demand for environmentally responsible products.

7 Reasons Why Short Run Injection Molding is the Best Choice for Your Business - Sustainability Advantages: Reducing Waste in Short Run Productions

| Advantage | Description | Impact on Sustainability |

|---|---|---|

| Reduced Material Waste | Short runs minimize excess material by producing only what is needed. | Decreases landfill contributions and promotes responsible material usage. |

| Lower Energy Consumption | Less time in production means lower overall energy used. | Helps reduce carbon footprint associated with manufacturing. |

| Quick Turnaround | Accelerated production processes for faster project completion. | Balances production demand with resource efficiency. |

| Flexibility in Design | Easily adaptable designs allow for prototype and testing iterations. | Minimizes waste from unsuccessful larger runs. |

| Local Sourcing Options | Encourages using local materials, supporting regional economies. | Reduces transportation emissions and promotes sustainability. |

| Smaller Inventory Needs | Producing smaller quantities lowers storage demands. | Limits excess production and resource use. |

| Enhanced Quality Control | Short runs allow for more focus on quality in production. | Reduces defective rates and waste materials. |

Related Posts

-

Quality Driven Global Success of Prototype Injection Molding from China

-

Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

-

Exploring Innovative Alternatives to Injection Moldable Plastics for Sustainable Production

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

Understanding Characteristics and Applications of Best Injection Molding Tooling Variants

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry