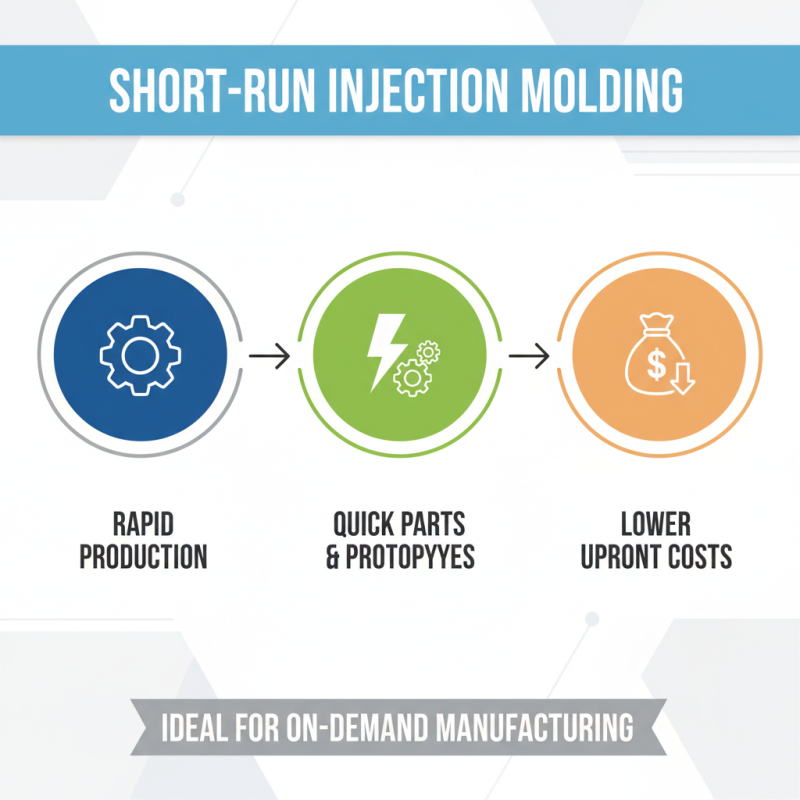

Why Short Run Injection Molding is the Best Choice for Rapid Production Needs

In today's fast-paced manufacturing landscape, businesses are constantly on the lookout for efficient ways to meet their production demands while minimizing costs. Short run injection molding stands out as an optimal solution for companies facing rapid production needs. This process allows for the quick turnaround of small quantities of custom-designed parts, making it particularly appealing for prototypes, limited batch productions, or products requiring design iterations. The flexibility and speed of short run injection molding enable manufacturers to respond swiftly to market changes, ensuring they stay competitive.

Furthermore, short run injection molding not only reduces production lead times but also offers significant cost savings. Unlike traditional injection molding methods that require large volumes to justify the upfront costs of tooling, short run injection molding eliminates these barriers, allowing businesses to produce high-quality parts without the necessity of large-scale investments. As a result, companies can allocate resources more effectively and scale their production as needed without financial strain. This approach not only empowers innovation but also aligns perfectly with the evolving demands of consumers in a rapidly changing marketplace. In conclusion, for enterprises looking to harmonize efficiency with cost-effectiveness in their production processes, short run injection molding emerges as the best choice for addressing their urgent needs.

Understanding Short Run Injection Molding and Its Advantages

Short run injection molding is an efficient manufacturing process that caters specifically to rapid production needs. This method allows for the quick creation of parts and prototypes, making it an ideal choice for industries that require immediate solutions. The principle behind short run injection molding is its ability to produce smaller batches of high-quality plastic parts without the significant upfront costs associated with traditional large-scale production methods. This flexibility helps businesses adapt to market demands without overcommitting to inventory.

One of the primary advantages of short run injection molding is its speed. Production times are significantly reduced, allowing for faster turnaround on projects. This quick pace is particularly beneficial for companies testing new product designs or entering emerging markets where time-to-market can be critical. Furthermore, short run injection molding typically involves less complex tooling, which minimizes initial investments and facilitates more efficient modifications. As a result, companies can iterate on designs and respond to feedback more promptly, ultimately leading to better products and satisfied customers.

Key Factors Driving the Need for Rapid Production

Rapid production is increasingly vital in today’s fast-paced market, driven by several key factors. First, the demand for custom products is growing as consumers seek personalized solutions. Companies are responding by designing unique items that require quick turnaround times, necessitating efficient production methods. Short run injection molding becomes an ideal technique, allowing manufacturers to produce limited quantities without the significant lead times associated with traditional methods.

Another factor is the need for rapid prototyping. Businesses often require functional prototypes to test and validate designs before mass production. Short run injection molding provides the flexibility to create prototypes in a shorter timeframe, enabling agile adjustments based on feedback. This iterative process is crucial for innovation, as it allows firms to refine their products quickly and stay ahead of competitors in a dynamic marketplace. Additionally, as production cycles shorten, the ability to pivot quickly in response to consumer trends enhances a company's competitive edge.

Comparison of Short Run Injection Molding vs. Traditional Methods

Short run injection molding is gaining traction as a preferred approach for companies with rapid production needs, particularly when compared to traditional manufacturing methods. According to a recent report by the Plastic Industry Association, short run injection molding can reduce lead times by up to 50%, making it an ideal choice for businesses looking to accelerate their product development cycles. Traditional methods, such as CNC machining or manual assembly, often require longer setup times and incur higher costs per unit, especially for smaller production volumes.

One of the primary advantages of short run injection molding is the ability to produce high-quality parts in a fraction of the time. A study from the Society of Manufacturing Engineers indicates that short run processes can achieve accuracies within ±0.005 inches, which is critical for industries such as medical devices and automotive components. In contrast, traditional methods may struggle to maintain similar precision while being constrained by slower production speeds, especially when scaling up to meet demand.

Tips for successful implementation of short run injection molding include carefully selecting materials that are optimized for the intended application and utilizing advanced simulation software to design molds. Additionally, maintaining a flexible production schedule can help companies adapt quickly to market changes and customer feedback, minimizing wasted resources and maximizing efficiency. Adopting these strategies can further enhance the benefits of short run injection molding, solidifying its reputation as the go-to solution for speedier production without sacrificing quality.

Comparison of Short Run Injection Molding vs. Traditional Methods

Cost Efficiency in Short Run Injection Molding Projects

Short-run injection molding is increasingly recognized for its cost efficiency, particularly in projects where rapid production is essential. Unlike traditional high-volume manufacturing methods, short-run injection molding allows companies to produce smaller quantities of parts without the burden of high upfront costs or extensive lead times. This adaptability makes it ideal for businesses looking to prototype new products, conduct market testing, or satisfy specific customer demands that do not require mass production. By utilizing shorter production runs, companies can reduce overhead costs and allocate their budgets more effectively.

Moreover, the efficiency of short-run injection molding extends beyond mere cost savings. The process allows for quicker turnaround times, which can significantly benefit organizations needing to respond swiftly to market changes or emerging opportunities. Lower production volumes mean that manufacturers can quickly pivot their designs based on feedback and insights, streamlining the path from concept to market. This nimbleness not only minimizes waste but also optimizes resource allocation, making it a prudent choice for businesses focused on innovation and responsiveness in a competitive landscape.

Applications and Industries Benefiting from Quick Production Solutions

Short run injection molding has emerged as a pivotal solution across multiple sectors that require quick production capabilities. Industries such as automotive, consumer electronics, and medical devices greatly benefit from the rapid prototyping and low-volume production offered by this method. According to a report from MarketsandMarkets, the global injection molding market is projected to reach $370 billion by 2025, with a significant portion driven by the demand for shorter production cycles and flexibility, especially in industries adapting to fast-changing consumer preferences.

In the automotive industry, the need for rapid prototyping has become increasingly important, as companies strive to reduce time-to-market for new models. Short run injection molding allows for quick iterations of design, enabling manufacturers to test and refine components before committing to large-scale production. Similarly, in the consumer electronics sector, where product lifecycles are often measured in months, the ability to quickly produce small batches of parts ensures that companies can keep pace with innovation and consumer demands. A study by Grand View Research indicates that the medical device market alone is expected to surpass $400 billion by 2027, supporting the need for rapid, reliable part production to comply with stringent regulations and market requirements.

Moreover, industries such as packaging and aerospace are increasingly adopting short run injection molding for their low-volume needs. It allows manufacturers to create tailored solutions that meet specific regulatory or functional requirements without the high costs associated with traditional manufacturing methods. As businesses continue to prioritize agility and responsiveness, short run injection molding will play a crucial role in shaping various sectors to align with evolving market trends and consumer expectations.

Why Short Run Injection Molding is the Best Choice for Rapid Production Needs - Applications and Industries Benefiting from Quick Production Solutions

| Application | Industry | Production Time (Days) | Typical Order Size | Benefits |

|---|---|---|---|---|

| Prototype Components | Automotive | 5-10 | 50-500 | Faster iteration, lower costs |

| Medical Device Parts | Healthcare | 7-12 | 100-1000 | High precision, meet regulatory standards |

| Consumer Goods | Consumer Products | 3-7 | 500-2000 | Rapid response to market demands |

| Specialty Packaging | Packaging | 2-5 | 300-1500 | Cost-efficient production runs |

| Custom Tooling | Industrial | 10-20 | 10-100 | Tailored solutions for specific needs |

Related Posts

-

Quality Driven Global Success of Prototype Injection Molding from China

-

Exploring the Advantages of PP Injection Molding for Sustainable Product Design

-

Exploring the Benefits and Applications of Various Injection Molding Products in Today's Industry

-

Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

-

Common Challenges Faced in Mold Plastic Injection Processes

-

7 Reasons Why Short Run Injection Molding is the Best Choice for Your Business