7 Unmatched Strategies for Optimizing Your Injection Tooling Process

In today's competitive manufacturing landscape, optimizing your injection tooling process is more critical than ever. As industries seek to enhance efficiency, reduce costs, and improve product quality, understanding the intricacies of injection tooling becomes paramount. This blog explores seven unmatched strategies that can transform your approach to injection tooling, enabling you to streamline operations and achieve superior results. Whether you are a seasoned professional or new to the field, implementing these strategies can lead to significant improvements in production timelines and resource management.

From advanced material selection to innovative maintenance practices, these insights aim to empower you with the knowledge necessary to refine your injection tooling process, ultimately driving your business towards greater success. Join us as we delve into practical techniques that will reshape your injection engineering efforts and elevate your manufacturing capabilities.

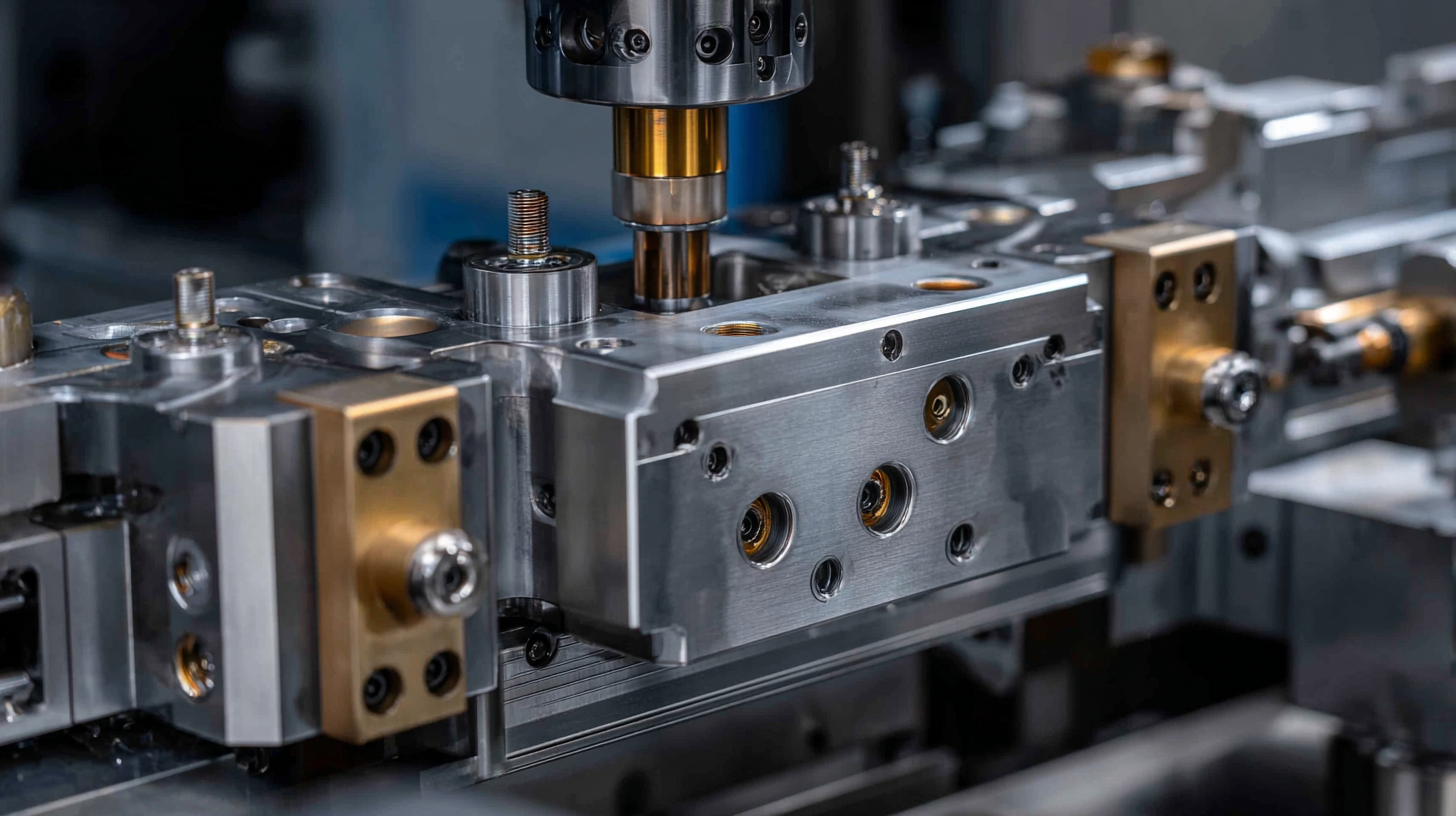

Understanding the Importance of Injection Tooling Optimization

Injection tooling optimization is crucial for manufacturers aiming to enhance production efficiency and reduce costs. According to a report by the Fluence Analytics, optimizing injection molding processes can lead to a 20-30% reduction in material waste and significant improvements in cycle times. This highlights the importance of refining tooling processes, as inefficiencies can severely impact the bottom line. Furthermore, the Advanced Manufacturing Office estimates that effective tooling strategies can increase production rates by up to 50%, underscoring the need for ongoing optimization.

To achieve optimal performance, manufacturers should regularly assess their tooling systems. One effective tip is to conduct routine maintenance checks, which can prevent costly downtime and extend tool life. Moreover, incorporating advanced technologies, such as automated monitoring systems, can significantly enhance real-time data analysis, allowing for quicker adjustments during production. Adapting to these modern approaches not only streamlines processes but also ensures that resources are utilized most efficiently.

Lastly, collaboration with tooling suppliers can lead to innovative solutions tailored to specific production needs. Leveraging the expertise of industry partners can provide insights into best practices and emerging technologies, further enhancing the overall injection tooling process. By embracing these strategies, businesses position themselves to remain competitive in an increasingly demanding industry landscape.

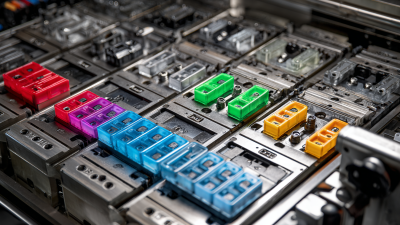

Injection Tooling Process Optimization Strategies

Identifying Key Metrics for Measuring Tooling Performance

When it comes to optimizing the injection tooling process, identifying key metrics for measuring tooling performance is essential. According to a study by the Association for Manufacturing Technology (AMT), manufacturers that implement data-driven performance metrics can see efficiency gains of up to 15% within the first six months. Key metrics to focus on include cycle time, tooling uptime, and overall equipment effectiveness (OEE). These metrics provide a comprehensive understanding of how well your tooling is performing and can help pinpoint areas for improvement.

Cycle time, for instance, is crucial as it directly affects production rates. A report from the Society of Plastics Engineers highlights that even a 10% reduction in cycle time can yield significant cost savings, potentially increasing profit margins by up to 20%. Additionally, monitoring tooling uptime can reveal potential bottlenecks in production, allowing for timely maintenance, which can further boost productivity. By systematically tracking these metrics alongside OEE, businesses can develop targeted strategies aimed at continuous improvement, leading to more streamlined operations and enhanced profitability.

Implementing Advanced Technologies to Enhance Tooling Efficiency

In today's fast-paced manufacturing environment, leveraging advanced technologies is essential to optimize the injection tooling process. One of the most significant innovations is the use of data analytics and machine learning algorithms. By analyzing historical performance data, manufacturers can predict potential failures and maintenance needs, significantly reducing downtime and enhancing overall efficiency. This proactive approach allows for informed decision-making, minimizing the risks associated with traditional reactive strategies.

Additionally, the integration of automation and IoT (Internet of Things) into the tooling process can drastically enhance productivity. Automated systems can monitor real-time performance, adjust operations dynamically, and ensure optimal conditions throughout the production cycle. IoT devices facilitate seamless communication between machines, enabling manufacturers to pinpoint inefficiencies and streamline workflows. As a result, the combination of these advanced technologies not only enhances tooling efficiency but also fosters an environment of continuous improvement and innovation, setting a new standard in the industry.

Streamlining Communication Between Design and Production Teams

Effective communication between design and production teams is crucial for optimizing the injection tooling process. A recent report by the Society of Manufacturing Engineers (SME) highlights that 70% of tooling issues stem from miscommunication during the design phase. When design teams do not clearly convey specifications or changes, it leads to costly revisions and production delays. Implementing structured communication protocols, such as regular cross-departmental meetings and standardized project management tools, can significantly mitigate these risks.

Moreover, leveraging collaborative platforms allows for real-time sharing of updates and feedback. According to a study conducted by the American Society for Quality (ASQ), organizations that utilize collaborative tools experience a 25% decrease in project completion time. By fostering an environment of transparency and collaboration, teams can ensure that design intentions are accurately translated into production realities. This not only enhances the efficiency of the tooling process but also drives innovation by allowing for a more iterative and responsive development cycle. The synergy between design and production ultimately leads to higher-quality products and improved overall performance in the injection molding industry.

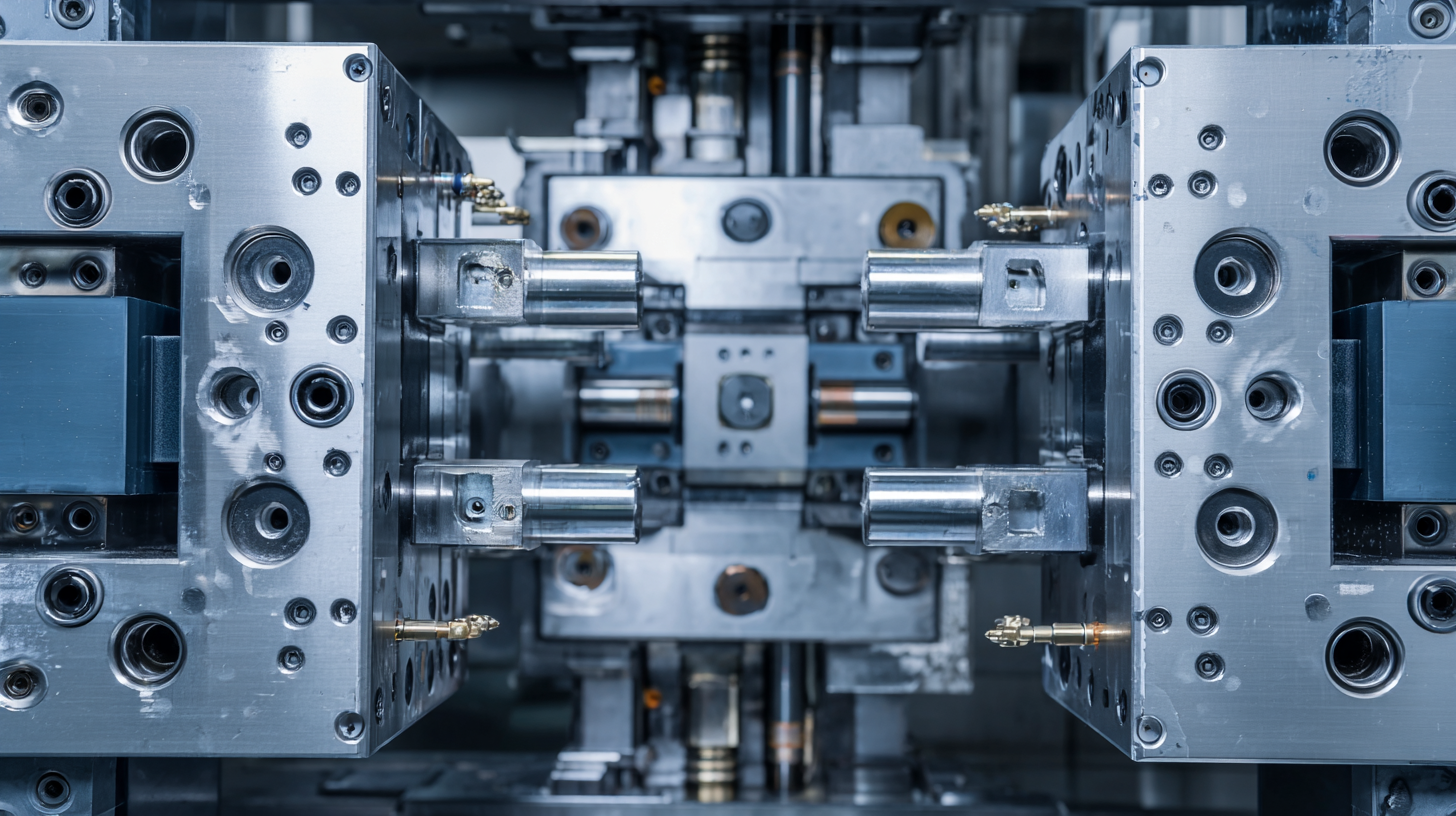

Developing a Comprehensive Maintenance Plan for Your Injection Tools

A comprehensive maintenance plan is crucial for optimizing the injection tooling process, as it not only extends the lifespan of the tools but also enhances production efficiency. According to a recent report by the Plastics Industry Association, regular and proactive maintenance can increase the productivity of injection molding machines by as much as 20%. This is particularly important considering that the total cost of mold maintenance can account for up to 30% of overall production expenses. By implementing a structured maintenance schedule, manufacturers can significantly reduce unexpected downtimes and repair costs.

Moreover, industry data suggests that 45% of manufacturers do not have a formal maintenance plan in place, which can lead to decreased performance and potential production halts. A well-developed maintenance plan should incorporate routine inspections, cleaning, and replacement protocols for critical components. This proactive approach not only promotes operational continuity but also ensures compliance with industry regulations. Companies that adopt such comprehensive strategies often report improved tool quality and reduced cycle times, ultimately driving higher profitability and customer satisfaction in the competitive injection molding market.

Related Posts

-

5 Key Benefits of Investing in Injection Tooling for Global Buyers

-

How to Choose the Right Injection Molding Tooling for Your Production Needs

-

Understanding Characteristics and Applications of Best Injection Molding Tooling Variants

-

Creative Examples of Successful Injection Molding Applications Across Industries

-

Mastering Injection Mold Fabrication: A Step-by-Step Guide for Beginners

-

Common Challenges Faced in Mold Plastic Injection Processes